1: Revolutionizing Welding Efficiency: The Critical Role of Speed Control in Modern Manufacturing

1.1: Welding Speed Directly Impacts Fusion, Strength, and Production Output

In high-volume industrial production, welding speed is no longer just a process variable—it is a determinant of product integrity and throughput. An excessively fast speed can result in insufficient metal fusion, creating weak points, inconsistent bead formation, or incomplete penetration. Conversely, excessively slow welding causes overheating, which may lead to grain growth, metallurgical defects, and unnecessary energy consumption. Both extremes reduce the structural reliability of welds.

1.2: Traditional Welding Systems Lack Real-Time Speed Regulation Capabilities

Conventional welding systems often depend heavily on operator experience or pre-programmed speed settings, which cannot dynamically respond to changing workpiece geometry or material behavior. This leads to fluctuations in weld quality and inefficiencies on the production line. Such limitations have become increasingly unacceptable in high-precision fields like automotive, aerospace, and appliance manufacturing.

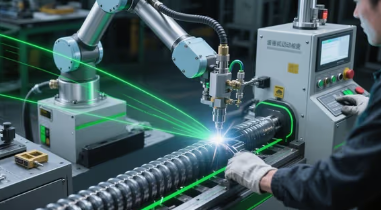

1.3: Pneumatic Seam Welder Introduces Intelligent Speed Adjustment for Consistent Quality

The Roll Welding Pneumatic Seam Welder addresses these issues head-on with its intelligent pneumatic-driven speed control system. This innovative design enables real-time speed adjustments based on task-specific welding parameters. The result: optimized heat input, stronger weld joints, and minimized operator intervention. It sets a new benchmark for quality assurance in modern welding automation.

2: Dynamic Speed Control in Action: Precision Welding Powered by Pneumatic Innovation

2.1: On-the-Fly Speed Adjustment for Diverse Welding Applications

A standout feature of the Roll Welding Pneumatic Seam Welder is its capacity to fine-tune speed dynamically during active welding cycles. This ensures that regardless of changes in material thickness, shape complexity, or weld joint type, the equipment adapts instantaneously—maintaining consistent arc characteristics and weld pool behavior across the board.

2.2: Seamless Transition Between Routine and Complex Welding Tasks

Whether handling simple repetitive tasks or intricate, multi-phase welding operations, the welder can transition without manual recalibration. Its pneumatic system senses pressure and load variation to deliver the most effective speed in each moment. This provides manufacturers with flexibility, especially beneficial in mixed production environments where switching between product types is frequent.

2.3: Flexibility Meets Performance with Precision Speed Control Mechanisms

This precision not only enhances weld quality but also reduces the need for rework or post-weld inspection interventions. Manufacturers can rely on the equipment to maintain high-quality welds with minimal fluctuation in joint performance. As a result, it reduces operational costs and improves delivery timelines by enabling smooth, interruption-free production cycles.

3: Boosting Production and Weld Quality: Seamless Integration of Speed, Stability, and Consistency

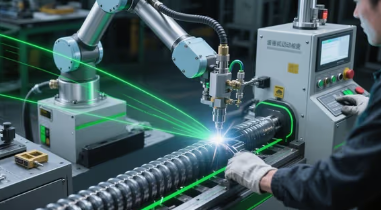

3.1: Uniform Weld Quality at Scale with Controlled Welding Speeds

Large-scale production demands uniformity—every weld must meet the same standard of strength, appearance, and durability. The Roll Welding Pneumatic Seam Welder ensures this by maintaining a precise and stable welding speed across long production runs. It eliminates issues such as irregular bead shapes, spatter accumulation, or inconsistent penetration depth that typically result from manual or poorly controlled processes.

3.2: Enhanced Process Coordination Across the Welding Line

Speed precision contributes to better synchronization between multiple process steps, including material feeding, alignment, and post-weld cooling. The pneumatic system allows the welder to seamlessly integrate with automated production lines, minimizing bottlenecks and promoting lean manufacturing principles. The result is a smoother production rhythm with fewer stoppages and reduced operator workload.

3.3: Stable Welding Performance Under Challenging Conditions

When faced with variable environmental factors such as temperature shifts, vibration, or complex geometries, traditional welders often lose consistency. The Roll Welding Pneumatic Seam Welder, however, sustains performance through high-speed pneumatic feedback loops that adjust welding speed in milliseconds. This ensures sealed, uniform, and high-strength joints regardless of external or internal variability in the work environment.