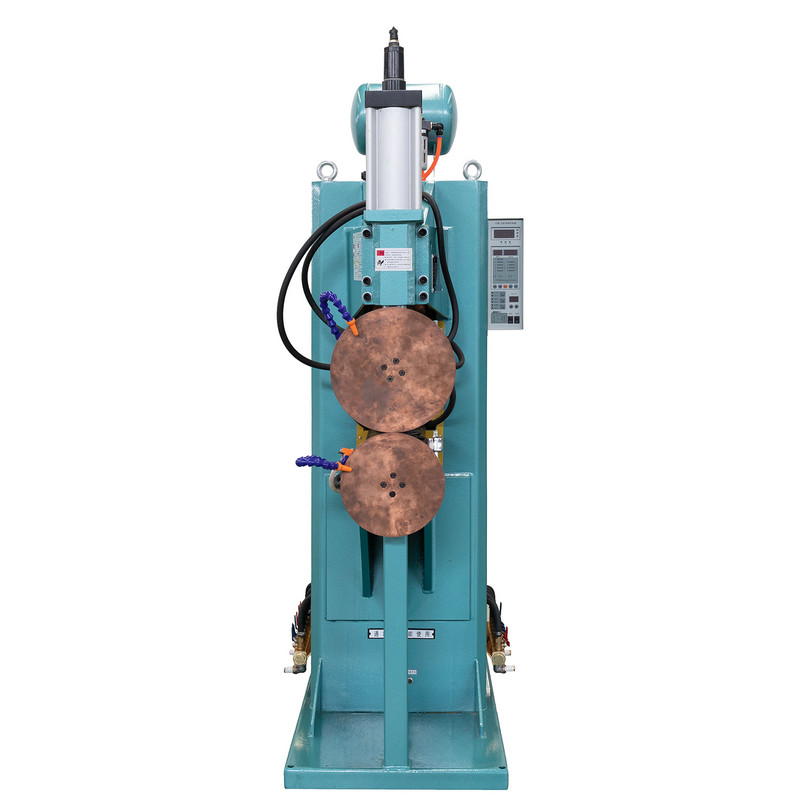

The FN-50 Roll Welding Pneumatic Seam Welder is a versatile machine designed for welding both sealing and non-sealing sheet metal joints. It accommodates metal thicknesses ranging from 0.1mm to 2.5mm, making it suitable for a wide variety of industrial applications. The machine is equipped with a three-phase stepless speed regulation drive, ensuring stable and convenient welding speed adjustments. It supports vertical and horizontal welding configurations, allowing flexibility for different types of box-shaped workpieces.

Detailed Description

- Wide Application Range: Suitable for welding sealing sheet metal joints as well as ordinary non-sealing metal parts.

- Material Compatibility: Handles metal thicknesses from 0.1mm to 2.5mm, accommodating most standard sheet metal materials.

- Speed Control: Features a three-phase stepless speed regulation drive, providing precise and stable welding speed adjustment for consistent weld quality.

- Flexible Welding Orientation: Can operate in vertical or horizontal welding modes, adapting to diverse workpiece shapes and sizes.

- Pneumatic Drive System: Ensures smooth and reliable operation with minimal manual intervention.

- High Efficiency and Stability: Designed for continuous operation, offering consistent welds with reduced downtime.

- User-Friendly Operation: Simple adjustment mechanisms make the machine easy to operate and maintain.

FAQ

Q1: What is the maximum sheet thickness the FN-50 can weld?

A1: The machine can weld metal sheets with a thickness ranging from 0.1mm to 2.5mm.

Q2: Can the FN-50 handle both sealing and non-sealing joints?

A2: Yes, it is designed to weld both sealing and ordinary sheet metal joints efficiently.

Q3: How is the welding speed adjusted?

A3: The machine uses a three-phase stepless speed regulation drive, allowing for smooth and precise speed adjustment.

Q4: Is the machine limited to one welding orientation?

A4: No, it supports both vertical and horizontal welding, providing flexibility for different workpiece types.

Q5: What types of industries can use this welder?

A5: The FN-50 is suitable for industries involving sheet metal fabrication, HVAC components, box manufacturing, and other applications requiring sealed or general metal joints.