Key Advantages:

- Precision Control: Timing adjustment offers fine-tuned control over the welding cycle, crucial for material integrity and preventing over-welding.

- High Production Efficiency: The gear-type pedal operation enables quick and repeatable welds, boosting throughput in busy settings.

- Enhanced Weld Quality: Consistent timing leads to stronger, cleaner, and more aesthetically pleasing welds.

- Powerful Output: A substantial 35KW spot welding capability handles a broad spectrum of metal thicknesses and types.

Performance Features:

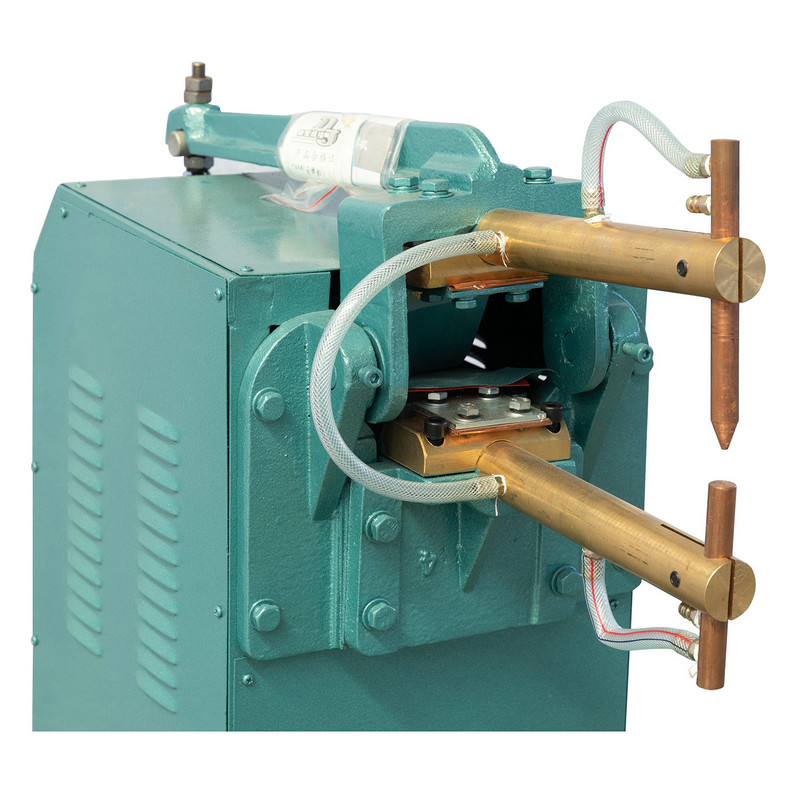

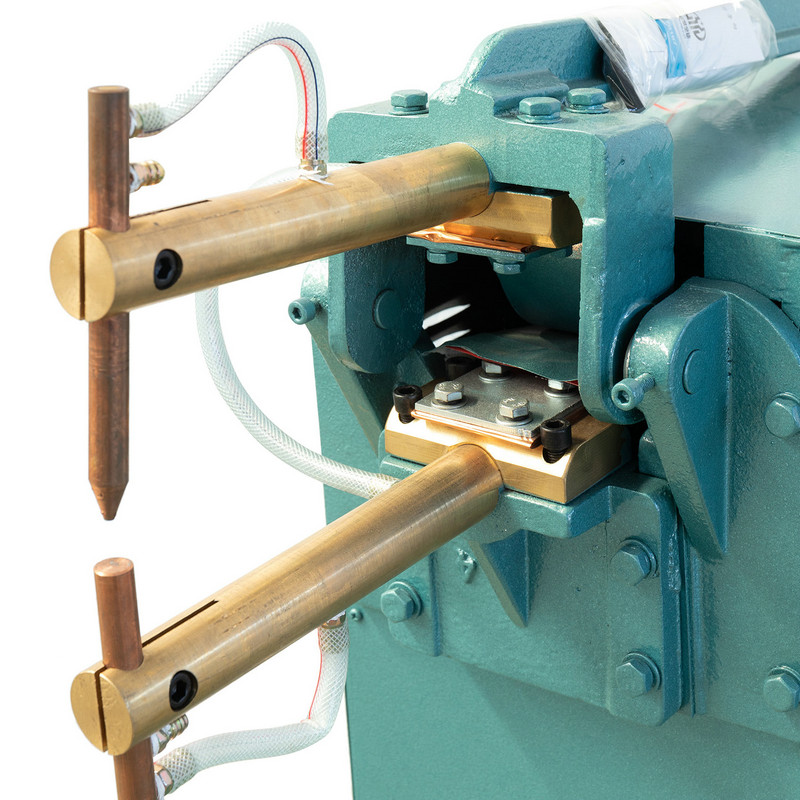

This AC pedal spot welder features a gear-type pedal mechanism, which provides robust and reliable mechanical action for consistent clamping pressure. The adjustable weld timer allows operators to set precise weld durations for optimal fusion. It boasts heavy-duty construction, built for continuous operation in industrial settings, ensuring long-term durability. It delivers stable performance, providing consistent power output for uniform weld penetration.

Applicable Scenarios:

- Automotive Component Manufacturing: For chassis parts, brackets, and sub-assemblies where precise spot welds are critical.

- High-Volume Metal Fabrication: Perfect for production lines requiring fast and repeatable spot welds.

- Appliance Manufacturing: Used for assembling metal casings and internal components.

- Industrial Equipment Production: Suitable for various joining tasks in the creation of machinery.

- HVAC Ducting: Ensures strong, leak-proof joints in ventilation systems.