This machine seamlessly combines powerful performance with operational flexibility (foot or hand operation) to deliver consistent, high-quality butt welds across a range of materials. Its robust construction and intelligent design make it an indispensable asset for workshops and production lines demanding reliability and efficiency.

Key Advantages

- Exceptional Welding Quality: Achieves clean, strong, and reliable butt welds with minimal material deformation, ensuring joint integrity in critical applications.

- Dual Operation Flexibility: Choose between foot-pedal operation for hands-free control or hand-lever operation for precise application of force, adapting to your specific workflow and operator preference.

- Robust & Reliable Performance: Built with industrial-grade components, including a heavy-duty welding transformer and an AC contactor-controlled main circuit, guaranteeing stability and long-term durability under demanding conditions.

- Ease of Use and Maintenance: Designed with the operator in mind, the machine features straightforward controls and is constructed for easy access to components, simplifying routine maintenance and minimizing downtime.

Product Features

- High-Capacity Transformer: A 25 KVA welding transformer provides ample power for welding a wide range of material diameters.

- Precise Energy Control: A 7-stage secondary voltage regulation allows for fine-tuned control over the welding current, enabling optimal parameters for different material types and thicknesses.

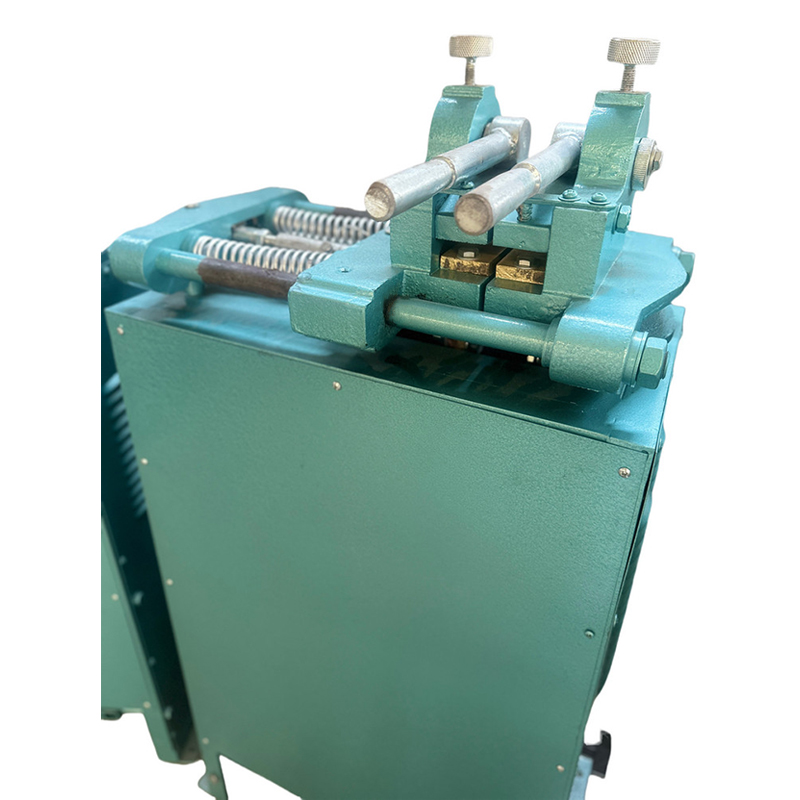

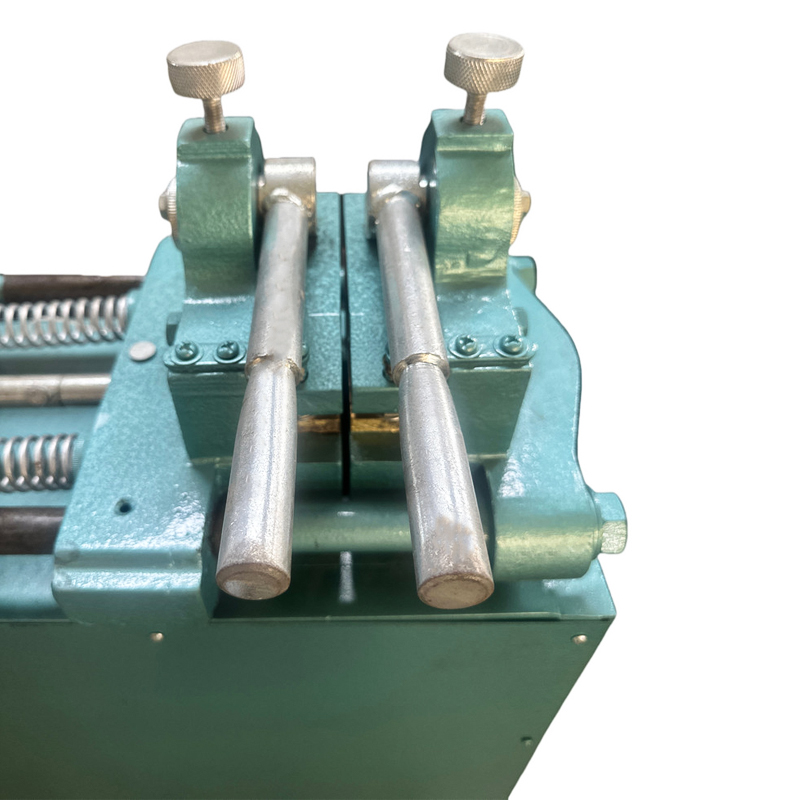

- Superior Clamping & Feeding Mechanism:

- Movable Electrode with Clamping: Ensures secure workpiece holding and excellent electrical contact.

- Maximum Upsetting Force: 1000N of force for a strong forge weld.

- Adjustable Feeding Stroke: A generous 22mm maximum stroke accommodates various upsetting requirements.

- Stable AC Contactor Control: The main switch circuit is governed by a reliable AC contactor, ensuring consistent welding performance and protecting the machine from electrical faults.

- Versatile Jaw Configuration: A maximum jaw distance of 16mm provides ample space for a variety of workpiece setups.

Applications

The UN1-25KW is exceptionally versatile and excels in diverse industrial sectors for butt welding applications, including:

- Automotive & Transportation: Welding of door frames, exhaust components, axle parts, and other structural elements.

- Construction & Metal Fabrication: Joining rebar, steel bars, fencing, and framework components.

- Electrical Industry: Creating continuous lengths of busbars, wires, and connectors from copper and aluminum alloys.

- Appliance Manufacturing: Assembly of heating elements, racks, and internal structural parts.

- General Repair & Maintenance: Ideal for job shops and maintenance departments for a wide array of metal joining and repair tasks.