The UN3-100KW is a state-of-the-art flash butt welding machine designed for superior performance, reliability, and ease of use in industrial applications. At its core is an advanced microcomputer controller that automates the entire welding process—clamping, flashing, upsetting, and connection—through personalized, programmable controls. This ensures unparalleled consistency and repeatability in every weld.

The machine produces exceptionally strong and high-integrity welds characterized by high strength, excellent density, and a flawless finish. It effectively eliminates common defects such as false welding, slag inclusions, and pores, resulting in joints that are not only structurally sound but also aesthetically pleasing.

Ideal for a wide range of hardware products, including:

- Round and square tubes

- Round steel bars and flat iron

- Bicycle and motorcycle rims

- Various other metal fabrications

Operating Instructions

1. Safety Precautions

- Ensure the machine is properly grounded and connected to a 380V/50Hz power supply.

- Wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and heat-resistant clothing.

- Keep the work area clean and free of obstructions.

2. Setup & Preparation

- Material Preparation: Securely clamp the workpieces (e.g., tubes, rims, round steel) within the machine’s jaws, ensuring they are properly aligned. Do not exceed the maximum jaw distance of 40mm or the maximum welding diameter of Ø20mm for steel.

- Power On: Switch on the main power supply.

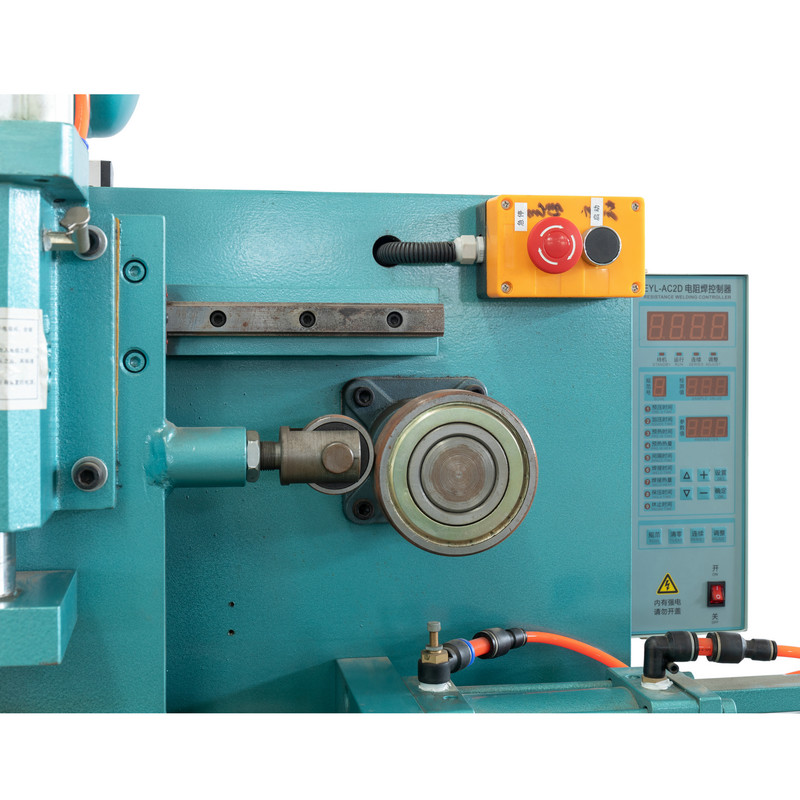

- Parameter Selection: On the microcomputer controller, input the welding parameters suitable for your material type, thickness, and desired weld quality. The stepless voltage regulation allows for fine-tuning the secondary voltage.

3. Welding Cycle Initiation

- Once the parameters are set and the workpieces are aligned, initiate the automated cycle from the controller.

- The microcomputer will sequentially execute the following stages:

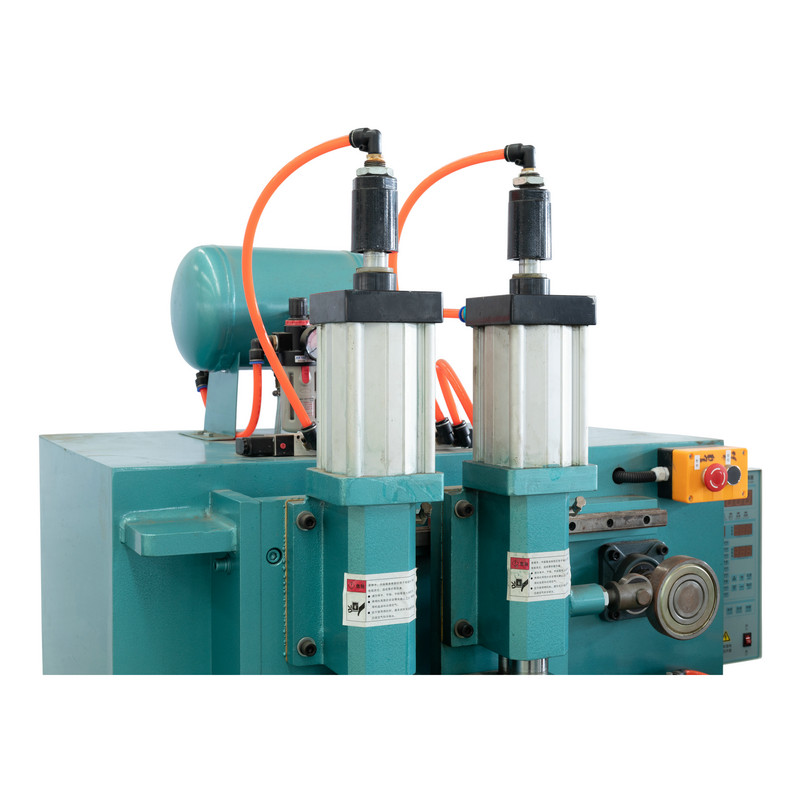

- Clamping: Applies up to 6100N of force to securely hold the workpieces.

- Flashing: Controls the voltage to create a precise flashing action, heating the ends of the materials to forging temperature.

- Upsetting: Automatically forges the heated parts together with a force of up to 2500N, expelling impurities and creating a dense weld.

- Connection & Stop: Completes the weld cycle and comes to a stop.

4. Post-Weld

- Carefully remove the welded product. It will be extremely hot.

- Allow the product to cool before handling or performing any post-processing.

- Inspect the weld for the characteristic strong, dense, and clean finish the machine is designed to produce.

Note: Always refer to the full manufacturer’s manual for detailed maintenance schedules, troubleshooting guides, and safety information specific to your model.