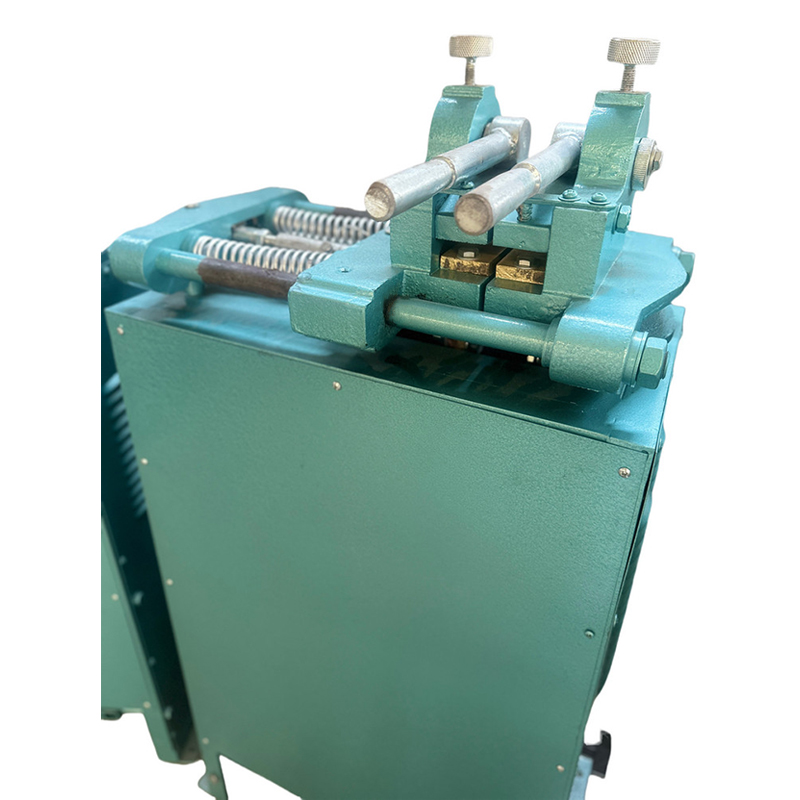

The UN1-1KW is a robust and reliable hand-operated butt welding machine designed for precision joining of small-diameter wires and components. Encased in a durable metal shell, this machine combines stable electrical performance with user-friendly manual operation, making it an indispensable tool for high-quality, consistent welds in various industrial and workshop settings.

Product Advantages

- Superior Weld Quality: Achieves clean, high-integrity butt joints with minimal deformation, ensuring excellent electrical conductivity and mechanical strength in the welded area.

- Exceptional Reliability & Stability: The core welding circuit is controlled by a heavy-duty AC contactor, guaranteeing consistent performance weld-after-weld and significantly reducing the risk of misfires or weak joints.

- Robust and Durable Construction: Housed in a sturdy metal shell, the UN1-1KW is built to withstand the rigors of daily use in industrial environments, ensuring long-term durability and protection for its internal components.

- Ease of Maintenance: Designed with simplicity in mind, the machine features easily accessible components, making routine checks and any necessary maintenance straightforward, minimizing downtime.

Product Features

- Precise Energy Control: Features an 8-stage secondary voltage regulation system, allowing operators to finely tune the welding power to perfectly match the material type and diameter for optimal results.

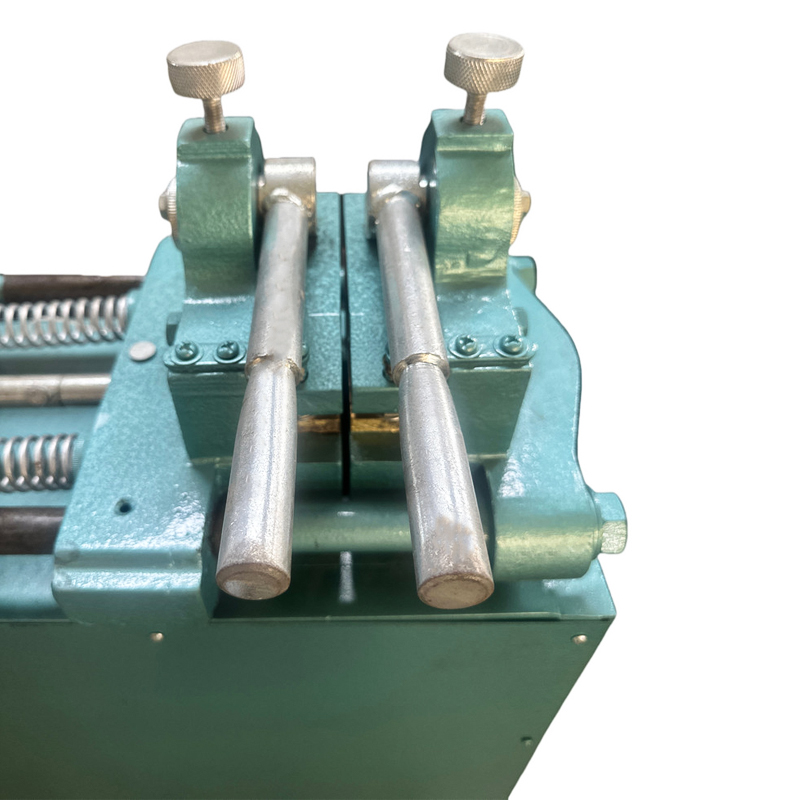

- Manual Operation & Control: The hand-operated mechanism provides the operator with complete tactile control over the welding and upsetting process, enabling precision and adaptability for various jobs.

- Optimized Welding Performance:

- Low No-Load Voltage: A safe and efficient no-load voltage range of 0.65 - 2.0V.

- Significant Upsetting Force: Delivers a maximum upsetting force of 10N to forge the molten materials together, creating a strong union.

- Adjustable Jaw Distance: A maximum jaw distance of 7mm and a feeding stroke of 3mm accommodate a range of workpiece sizes and geometries.

- Clear Technical Specifications:

- Primary Voltage: 220V (Standard AC outlet compatible)

- Rated Capacity: 1 KVA

- Rated Load Duration: 8% (Ideal for short, repetitive welding cycles)

Product Applications

The UN1-1KW is versatile and capable of performing high-quality butt welding on a range of materials, making it suitable for numerous industries:

- Electrical Manufacturing: Ideal for welding leads, motor windings, transformer coils, and connecting wires of various gauges.

- Electronics & Appliance Production: Perfect for joining internal wiring, component leads, and small conductive parts in appliances, power tools, and electronic devices.

- Metalworking & Fabrication: Used for crafting chains, rings, grilles, and other small fabricated metal items from wire stock.

- Repair and Maintenance Workshops: An essential tool for repairing broken wires, creating custom loops and links, and performing on-site maintenance tasks.

Supported Materials and Capacities:

- Low Carbon Steel: 0.6 mm — 2.0 mm diameter

- Copper: 0.6 mm — 1.6 mm diameter

- Aluminum & Copper-Aluminum Alloys: 0.6 mm — 1.6 mm diameter