The UN2-63KW is a high-performance, customizable pneumatic butt welding machine engineered for robust efficiency and exceptional weld quality. Designed to seamlessly weld steel bars, copper, aluminum, and a variety of other metal workpieces, this machine is an ideal solution for demanding construction, fabrication, and manufacturing environments.

Its core operation utilizes advanced pneumatic pressure to securely clamp the workpiece with unmatched stability and firmness, eliminating slippage and ensuring perfect alignment. A key feature is the moving clamp equipped with precision linear bearings, which guarantees incredibly smooth electrode movement and accurate positioning for consistent, repeatable results.

The UN2-63KW excels in operational efficiency by performing the entire welding process—clamping, upsetting, and welding—in a single, automated operation. This significantly boosts productivity and reduces operator fatigue. At the heart of its precision is a microcomputer-based constant voltage control system, working in tandem with a sophisticated two-stage discharge process. This ensures optimal energy delivery for a clean, strong weld every time, with zero wear thanks to the durable linear bearing construction.

Operating Instructions

Important: Always prioritize safety. Wear appropriate Personal Protective Equipment (PPE) including welding gloves, goggles, and protective clothing before operation. Ensure the machine is properly grounded.

1. Preparation & Setup:

- Power Connection: Verify your power supply matches the machine’s configured voltage (220V or 380V). Connect the machine to the appropriate power source using the correct cable specifications.

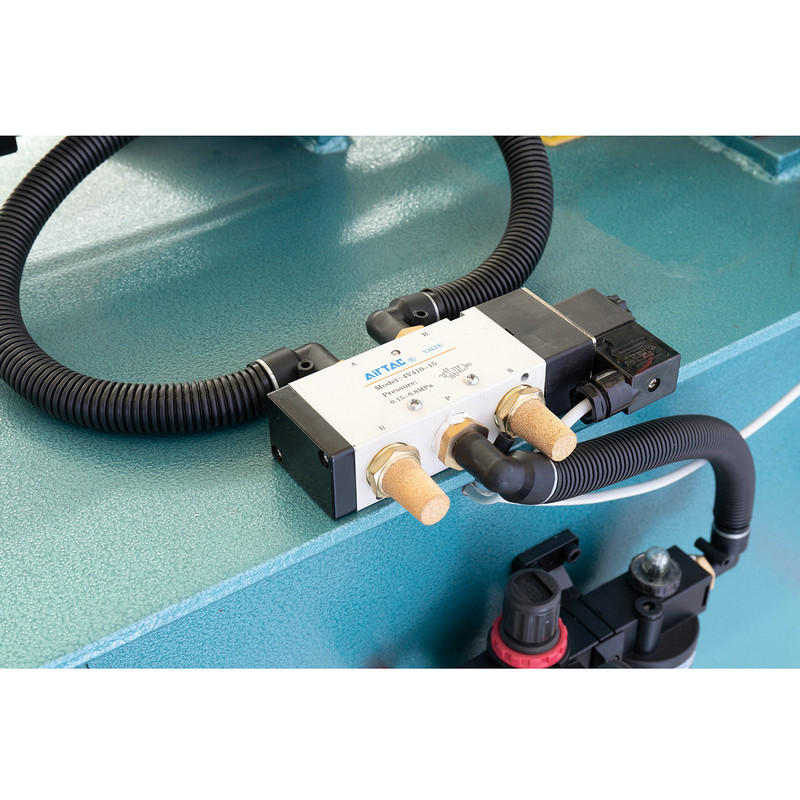

- Air Supply: Connect the machine to a clean, dry compressed air source. Ensure the pneumatic pressure is set to the recommended level for adequate clamping force.

- Workpiece Preparation: Clean the ends of the workpieces (e.g., steel bars) to remove rust, paint, oil, or debris. This is critical for achieving a high-quality weld.

2. Machine Configuration:

- Voltage Setting: Use the stepless voltage regulation control to set the secondary voltage according to the material type and thickness you are welding. Refer to the capability chart above for guidance.

- Stroke Adjustment: Set the maximum feeding stroke based on the required upsetting distance for your application (max 22mm).

3. Welding Procedure:

- Clamping: Place the prepared workpieces into the stationary and moving clamps. Activate the pneumatic system to securely clamp both pieces with stability and firmness.

- Initiating Weld: Start the welding cycle. The microcomputer control system will automatically manage the two-stage discharge process:

- Stage 1: Pre-heating the workpiece ends.

- Stage 2: Applying the main welding current and immediately followed by the upsetting force.

- Upsetting: The moving clamp, on its linear bearings, will smoothly and precisely forge the heated workpieces together under a force of up to 500N, creating a solid-phase weld.

- Completion: The cycle will complete automatically. Release the pneumatic clamps and remove the welded assembly.

4. Post-Operation:

- Allow the welded workpiece to cool before handling.

- Inspect the weld joint for consistency and quality.

- Turn off the power and air supply to the machine after use.

Note: For optimal performance and longevity, perform regular maintenance as per the manufacturer’s guidelines, ensuring the linear bearings and moving parts remain clean.