The UN2-80KW is a high-performance, industrial-grade pneumatic butt welding machine engineered for superior efficiency, precision, and reliability in demanding construction and fabrication environments. It leverages advanced pneumatic pressure to secure workpieces with exceptional stability and firmness, ensuring consistent, high-quality welds every time.

Equipped with precision linear bearings, the moving clamp facilitates seamless electrode movement and exact positioning with zero wear over time. This robust design allows the machine to perform clamping, upsetting, and welding in a single, automated step, drastically boosting productivity and reducing operator fatigue.

At its core, the UN2-80KW features a sophisticated microcomputer-controlled constant voltage system with two-stage discharge. This intelligent system provides precise control over the welding process, optimizing energy use and weld integrity. Combined with its robust build and versatile performance, this machine is the ideal solution for a wide range of metal joining applications.

Key Features & Benefits:

- High-Efficiency Operation: Completes clamping, upsetting, and welding in one seamless cycle.

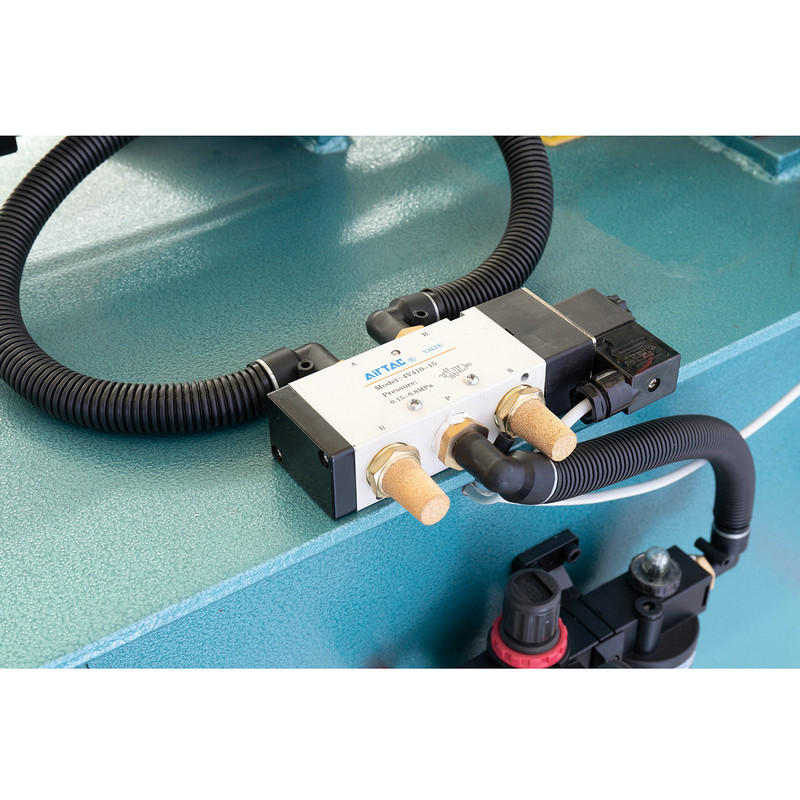

- Pneumatic Clamping System: Ensures stable and firm workpiece securing with a maximum upsetting force of 1000N.

- Precision Linear Bearings: Guarantee smooth movement, precise positioning, and exceptional durability with zero wear.

- Microcomputer Intelligent Control: Features a constant voltage system with two-stage discharge for superior, consistent weld quality.

- Stepless Voltage Regulation: Allows for incredibly fine-tuned control over the secondary voltage (0.65-6.0V) to match any job requirement.

- Exceptional Versatility: Capable of welding low carbon steel (3.5-10.0mm), copper (3.0-6.0mm), and aluminum (3.0-6.0mm).

- Robust Construction: Designed to enhance adaptability and performance in a broad range of construction environments.

Operating Instructions & Guidelines

1. Safety Precautions

- Ensure the machine is properly grounded and connected to a 380V power supply.

- Wear appropriate Personal Protective Equipment (PPE): welding gloves, safety glasses, and flame-resistant clothing.

- Keep the work area clean, dry, and free of flammable materials.

2. Pre-Operation Setup

- Power Check: Verify that the incoming power supply matches the machine’s 380V requirement.

- Air Supply: Connect the machine to a clean, dry compressed air source as per the manufacturer’s recommended pressure rating.

- Workpiece Preparation: Clean the materials to be welded (low carbon steel, copper, or aluminum) to remove any rust, paint, oil, or debris. Ensure the material thickness is within the machine’s specified capacity.

- Machine Settings:

- Use the stepless voltage regulation to set the appropriate no-load voltage for your specific material type and thickness.

- Program the desired parameters into the microcomputer control system for the two-stage discharge process.

3. Operation Sequence

- Position: Place the pre-cleaned workpieces into the clamps, ensuring they are aligned correctly.

- Initiate: Activate the machine cycle (usually via a foot pedal or two-hand control for safety).

- Automatic Cycle: The machine will automatically:

- Clamp: The pneumatic system will firmly secure the workpieces.

- Weld: The microcomputer will initiate the two-stage discharge cycle, applying the precise voltage and force.

- Upset: The moving clamp will apply the upsetting force (up to 1000N) and feeding stroke (up to 22mm) to forge the weld.

- Completion: The clamps will retract automatically once the cycle is complete. Carefully remove the welded assembly.

4. Maintenance

- Regularly inspect and clean the electrodes and clamping jaws.

- Check the linear bearings for smooth operation; they are designed for zero wear but should be kept free of debris.

- Periodically check all electrical connections and air lines for tightness and wear.

- Do not exceed the 20% rated load duration to prevent overheating. Allow the machine to cool after intensive use.

Note: Always consult the full manufacturer’s manual for detailed safety information, maintenance schedules, and troubleshooting guides before operating the machine.