Key Advantages:

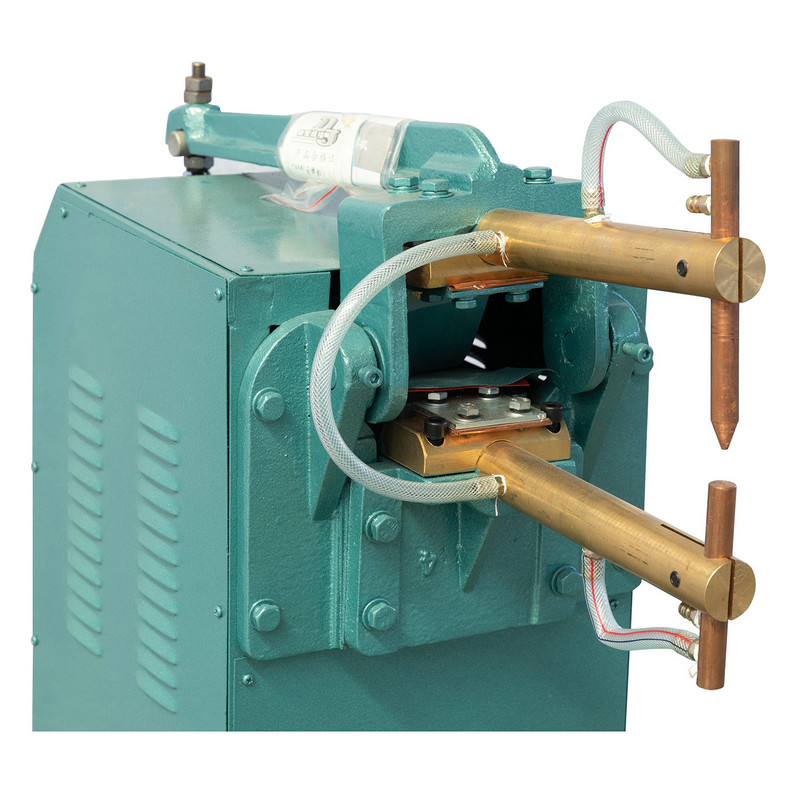

- Compact Footprint: Its small size makes it suitable for workshops, garages, and facilities where space is at a premium, without sacrificing power.

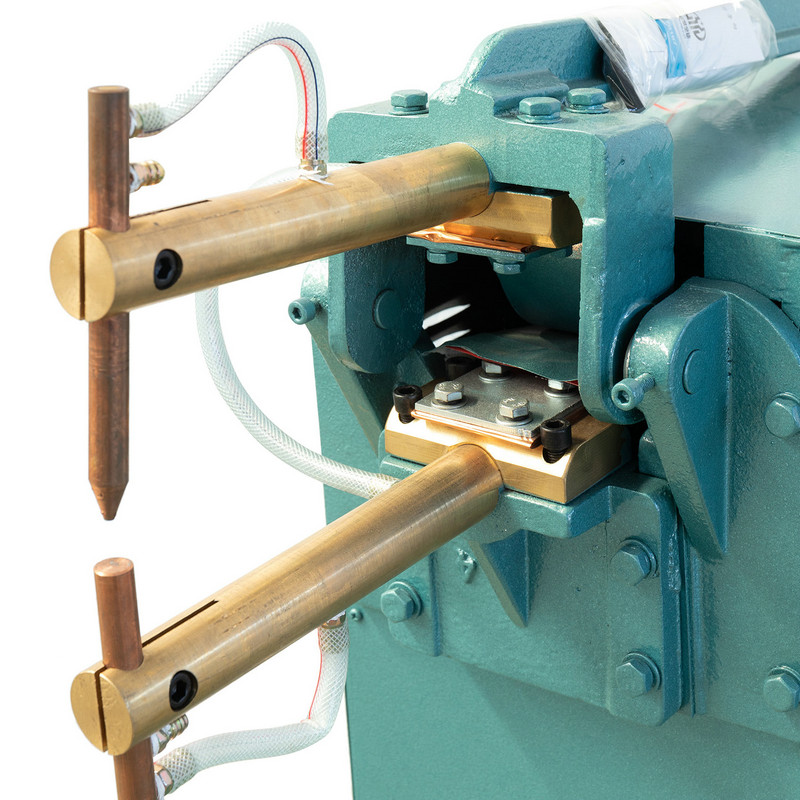

- High Power Output: Despite its size, the DN1-25KW delivers a substantial 25KW of power, capable of handling a wide range of materials and thicknesses.

- Versatile Voltage Input: Operates on both 220V and 380V AC, offering flexibility for different electrical setups. The primary voltage for the DN1-25KW model is 380V.

Performance Features:

- Efficient AC Welding: Provides consistent and strong welds for various metals, including copper and stainless steel.

- User-Friendly Operation: Designed for ease of use, making it accessible for both experienced welders and newcomers. This is a pedal type spot welder.

- Durable Construction: Built to withstand regular use in demanding environments.

Applicable Scenarios:

- Small-Scale Manufacturing: Suitable for producing smaller batches of metal components.

- Sheet Metal Fabrication: Effective for joining sheet metal in applications like ductwork, enclosures, and light industrial parts.

- Automotive Repair: Applicable for various welding tasks in auto body shops.

- HVAC and Appliance Repair: Good for quick and strong repairs on metal casings and components.

- Hobbyist & DIY Projects: A powerful option for serious home users working with metal.

This high power spot welding machine is also known as a spot welding machine 25kw, DN1-25KW spot welder, small size spot welder 220v, 380v AC spot welding equipment, portable spot welding machine, industrial spot welder 25kw, resistance spot welding machine, metal spot welding machine, handheld spot welding equipment, compact spot welding machine, inverter spot welder, and automatic spot welding machine.