Product Advantages

The DN2-16KW Metal Shell Pedal Type AC Spot Welding Machine offers several key advantages

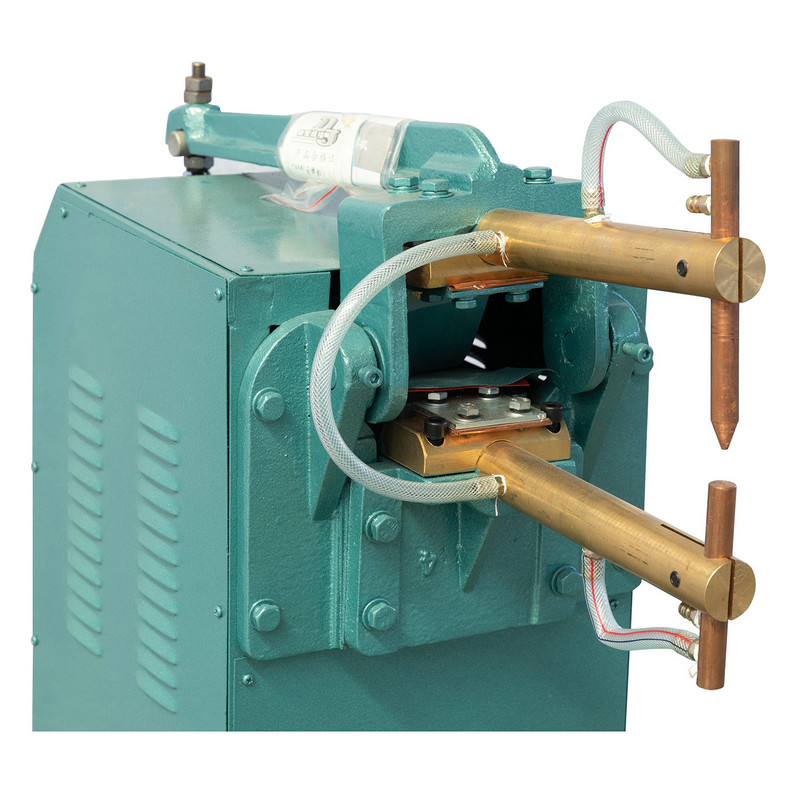

- Durable Metal Shell: Its robust metal shell spot welding machine provides exceptional protection against impacts and wear, ensuring a longer lifespan even in demanding industrial environments.

- Pedal Type Mechanism: The foot pedal control offers straightforward and efficient operation, allowing operators to quickly and precisely control the welding process. This makes it a portable pedal spot welder that’s easy to use.

- High Power Output (16KW): With a substantial 16KW power output, this machine handles a wide range of materials and thicknesses, making it a versatile high power pedal spot welder for different projects.

- Efficient AC Welding: Utilizing AC spot welding technology, it delivers quick and efficient welds, boosting productivity and minimizing energy consumption.

- User-Friendly Operation: Designed with ease of use in mind, this welding machine with foot pedal control features intuitive controls and straightforward adjustments, allowing operators to quickly master its functions and achieve optimal results.

Performance Characteristics

The DN2-16KW demonstrates impressive performance characteristics that distinguish it:

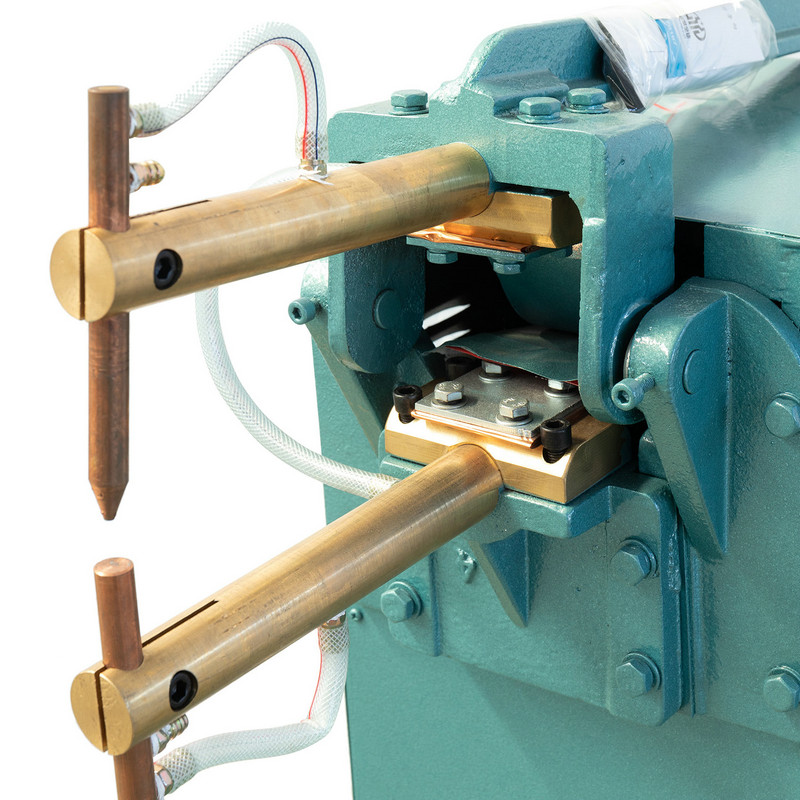

- Precise Welding Control: The pedal mechanism allows for fine-tuned adjustments of welding parameters, ensuring consistent and strong welds every time.

- Strong and Reliable Welds: Capable of producing high-strength spot welds that meet rigorous industry standards for critical applications. This resistance spot welder 16KW produces reliable results.

- Fast Welding Speed: Its efficient AC power delivery enables rapid welding cycles, significantly increasing production throughput.

- Stable Operation: Built with high-quality components, the machine provides stable and reliable performance, even during prolonged operation.

- Low Heat Distortion: The precise control and efficient welding process minimize heat-affected zones, reducing material distortion and improving the aesthetic quality of the welded parts.

- Adjustable Electrode Force: Users can easily adjust the electrode force to suit different material types and thicknesses, enhancing its adaptability.

Applicable Scenarios

The versatility and robust performance of the DN2-16KW Pedal Spot Welding Machine make it suitable for a wide array of applications across various industries:

- Automotive Manufacturing: This machine is well-suited for welding body panels, small components, and various sheet metal parts in vehicle production and repair.

- Sheet Metal Fabrication: It performs well for general sheet metal spot welding machine work, including the construction of enclosures, cabinets, and decorative metal items.

- Appliance Manufacturing: This machine is used in the production of household appliances for joining metal components.

- Electronics Industry: It is suitable for welding smaller components and enclosures in certain electronic manufacturing processes.

- Hardware and Tools Manufacturing: This machine applies to assembling various hardware items and tools requiring strong, precise spot welds.

- Construction and HVAC: It is useful for fabricating ductwork, frames, and other metal structures.

- Custom Fabrication Shops: This machine is a valuable asset for job shops that handle diverse welding projects with varying material types and thicknesses. This industrial spot welding machine is highly adaptable.

- Material Versatility: This spot welding machine for stainless steel is also capable of copper/aluminum spot welding machine applications, broadening its utility.