The UN2-150KW is a state-of-the-art, high-performance pneumatic butt welding machine engineered for superior efficiency and precision in metal joining applications. It is designed to stabilize and securely clamp workpieces using reliable pneumatic pressure, ensuring a consistent and powerful hold throughout the welding process.

A key feature is the moving clamp equipped with high-precision linear bearings, which facilitates seamless, frictionless electrode movement and allows for exact positioning of the workpieces. This advanced design, combined with a microcomputer-controlled constant voltage system and a sophisticated two-stage discharge process, guarantees exceptional weld quality, repeatability, and zero wear on critical moving components.

This machine streamlines production by performing clamping, upsetting, and welding in a single, automated step, significantly boosting overall productivity. Its robust design and advanced control system make it incredibly versatile for diverse construction, fabrication, and manufacturing environments.

Key Features & Benefits:

- Microcomputer-Controlled Constant Voltage: Ensures stable and precise energy delivery for perfect welds every time.

- Two-Stage Discharge Process: Optimizes heating and forging for superior joint integrity across various materials.

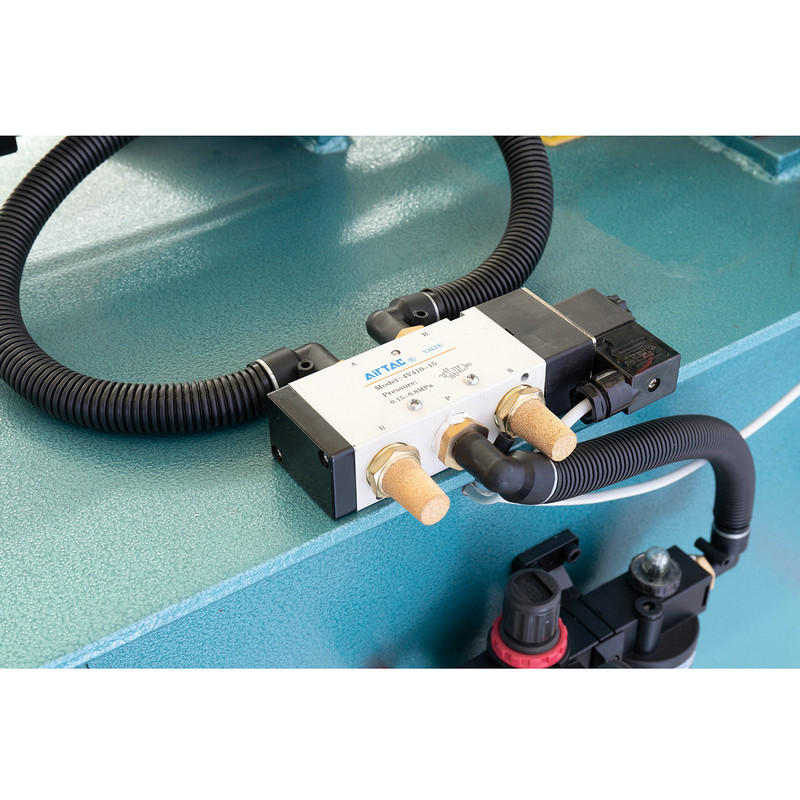

- Pneumatic Clamping & Upsetting: Provides powerful, consistent, and reliable force for secure holding and effective forging.

- High-Precision Linear Bearings: Enable smooth movement and precise positioning with zero wear, ensuring long-term accuracy and minimal maintenance.

- All-in-One Operation: Completes the entire welding cycle in one efficient step, maximizing throughput.

Operating Instructions

1. Safety Precautions

- Before operation, ensure the machine is properly grounded and all electrical connections are secure.

- Always wear appropriate Personal Protective Equipment (PPE), including safety glasses, heat-resistant gloves, and protective clothing.

- Ensure the work area is clean, dry, and free from flammable materials.

- Familiarize yourself with the emergency stop button location.

2. Setup & Preparation

- Connect the machine to a compatible 380V power source.

- Connect the factory air supply to the pneumatic system and adjust the pressure to the level specified in the machine’s manual for your material.

- Select the appropriate jaw inserts for the material type and diameter you will be welding.

- Securely mount the workpieces into the stationary and moving clamps, ensuring they are properly aligned and protruding the correct distance.

3. Machine Configuration

- Power on the machine and the microcomputer control system.

- Using the control panel, set the welding parameters. Key settings include:

- Clamping Pressure: Adjust based on material and diameter to prevent slipping.

- Upsetting Force & Stroke: Set the maximum force (up to 1200N) and stroke (up to 22mm) required to forge the heated parts together.

- Welding Voltage: Utilize the stepless voltage regulation (0.8-9.0V) to fine-tune the heat input for the specific material and cross-section.

4. Execution of Weld

- Double-check all settings and workpiece alignment.

- Initiate the automatic welding cycle. The machine will sequentially:

- Clamp: Apply pneumatic pressure to securely grip both workpieces.

- Weld & Upset: Automatically apply the two-stage discharge current to heat the interface, immediately followed by the pneumatic upsetting force to forge the molten metal together, creating a solid-state bond.

- The cycle will complete automatically.

5. Post-Weld & Shutdown

- Allow the newly formed weld joint to cool for a moment before handling.

- Open the clamps and carefully remove the welded assembly.

- After completing all welding tasks, power down the control system and disconnect the main power supply.

- Disconnect the air supply and perform basic housekeeping, keeping the machine and work area clean.

Note: Always consult the full manufacturer’s manual for detailed maintenance schedules, troubleshooting guides, and specific parameter recommendations for your application.