The UN2-50KW is a high-performance, microcomputer-controlled pneumatic butt welding machine engineered for superior stability, precision, and efficiency in demanding construction and fabrication settings. It integrates advanced pneumatic clamping with a sophisticated electrical system to deliver flawless welds on a variety of non-ferrous and ferrous metals.

Key Features & Benefits:

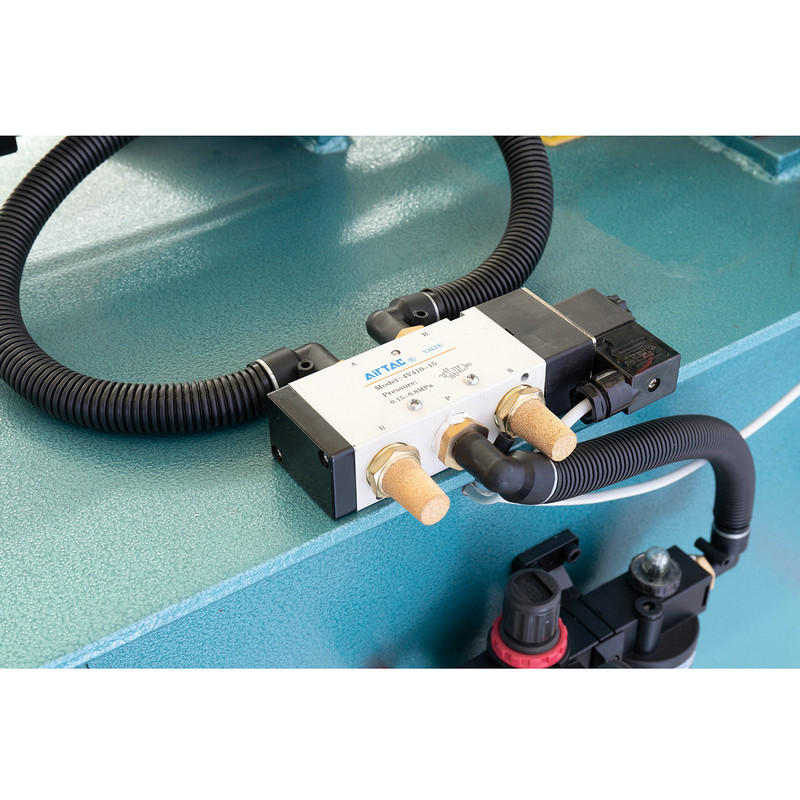

- Exceptional Workpiece Stability: A robust pneumatic pressure system secures the workpiece with unmatched stability and firmness, eliminating slippage and ensuring perfect alignment for every weld.

- Precision Movement & Zero Wear: The moving clamp is equipped with high-precision linear bearings, facilitating seamless electrode movement and accurate positioning. This design guarantees zero wear over time, ensuring long-term accuracy and reduced maintenance.

- Streamlined Operation: Engineered to perform clamping, upsetting, and welding in one seamless, automated operation, this machine significantly boosts production efficiency and reduces operator fatigue.

- Advanced Microcomputer Control: Features a constant voltage system with intelligent two-stage discharge control. This allows for precise management of the welding process, adapting to material variations for consistent, high-quality results.

- Versatile Material Application: Capable of welding a wide range of materials and thicknesses, including:

- Low Carbon Steel: 3.0 - 8.0 mm

- Copper: 2.0 - 6.0 mm

- Aluminum: 2.0 - 5.0 mm

Operating Instructions

1. Pre-Operation Safety & Setup Check

- Ensure the machine is properly grounded and connected to a 380V power supply.

- Verify that the air supply is connected, clean, and dry. Check for any pneumatic leaks.

- Inspect the electrodes for wear or damage and replace them if necessary. Ensure the maximum jaw distance (10mm) is sufficient for your workpiece.

- Select the appropriate welding program based on the material type and thickness (see specifications above).

2. Workpiece Preparation

- Clean the surfaces of the materials to be welded to remove any oxidation, oil, or contaminants. This is critical for achieving a strong weld, especially with aluminum and copper.

- Cut the workpieces to the required length, ensuring the ends are square for proper contact.

3. Machine Configuration

- Adjust the machine settings. Use the stepless voltage regulation to fine-tune the secondary voltage within the 0.65-2.8V range for optimal heat input.

- Set the desired upsetting force (up to 180N max) and feeding stroke (up to 22mm max) based on the material thickness and desired weld strength.

4. Execution of Weld Cycle

- Place the prepared workpieces into the clamping jaws, ensuring they are properly aligned and seated firmly against the electrodes.

- Initiate the automatic cycle. The machine will sequentially:

- Clamp: The pneumatic system will activate, securing the workpiece with immense stability.

- Weld: The microcomputer will initiate the two-stage discharge cycle, applying the set voltage and current to heat the materials.

- Upset: At the precise moment, the moving clamp will forge the materials together with the set upsetting force, completing the weld.

- Once the cycle is complete, the clamps will retract automatically.

5. Post-Operation

- Carefully remove the welded assembly (it may be hot).

- Inspect the weld bead for consistency and quality.

- Power down the machine and keep the work area clean.

Note: Always refer to the machine’s full manual for detailed safety procedures, maintenance schedules, and troubleshooting guides specific to your model.