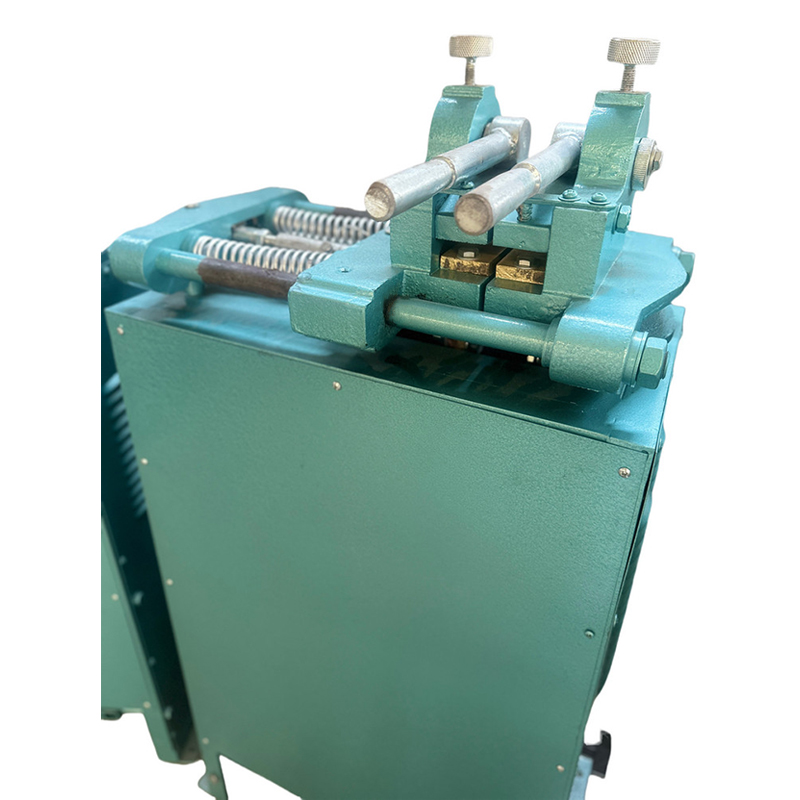

Engineered for industrial-grade performance, the UN1-150KW Foot-Operated Steel Bar Butt Welding Machine is a robust and reliable solution for creating high-integrity butt welds. This comprehensive system integrates advanced electrical control with a sturdy mechanical design to deliver consistent, high-quality welds across a wide range of conductive materials. It is the ideal choice for workshops and production lines where stability, ease of use, and minimal maintenance are paramount.

Product Advantages

- Unmatched Stability & Reliability: The utilization of a heavy-duty AC contactor in the main switching circuit guarantees consistent electrical flow, eliminating weld failures and ensuring every weld meets a high standard of quality and structural integrity.

- Exceptional Ease of Maintenance: Designed with serviceability in mind, the machine’s logical layout and accessible components significantly reduce downtime and lower long-term operating costs.

- Operator-Centric Design: The intuitive foot-operated control provides the welder with hands-free operation, enhancing safety and allowing for precise manipulation of the workpiece during the critical welding phase.

- Versatile Material Compatibility: Excellently welds a broad spectrum of materials, from common low-carbon steels to challenging non-ferrous metals like copper and aluminum, making it a highly adaptable asset.

Product Features

- High-Capacity Welding Transformer: At the heart of the machine, the 150KW transformer delivers the powerful, controlled current necessary for creating perfect fusion welds in bars and profiles up to its maximum capacity.

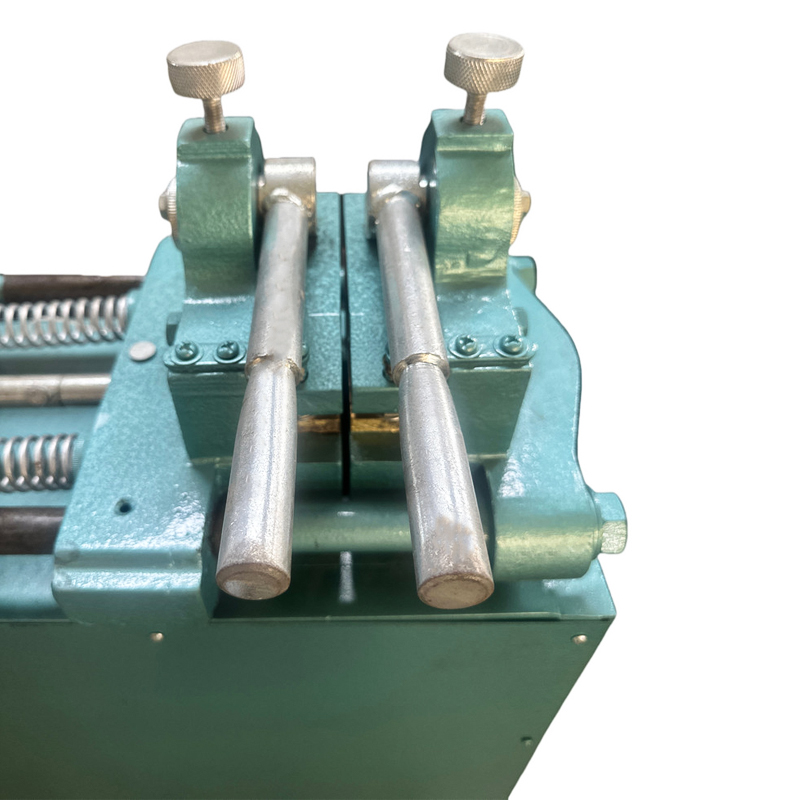

- Precision Electrode System: Features a stationary electrode and an adjustable electrode clamp, allowing for quick and secure accommodation of various workpiece sizes and shapes, ensuring optimal alignment and current conduction.

- Robust Pressure-Fed Mechanism: A reliable mechanical system provides the consistent and forceful upset pressure required to forge the molten materials together, creating a strong, defect-free weld nugget.

- Simplified Control Systems: The foot-operated pedal gives the operator complete control over the welding cycle, enabling a natural and responsive workflow for both high-volume tasks and custom jobs.

- Durable Industrial Construction: Built with a heavy-duty steel frame and high-quality components, this machine is designed to withstand the rigors of a demanding industrial environment.

Product Applications

The UN1-150KW Butt Welding Machine is a versatile workhorse across diverse industries that require strong, consistent metal joining:

- Construction & Rebar Fabrication: Ideal for splicing reinforcing steel bars (rebar) for concrete structures, foundations, and columns.

- Metalworking & Manufacturing: Perfect for creating frames, grilles, fencing, and welding parts for machinery and automotive components.

- Non-Ferrous Metal Fabrication: Excellently suited for welding copper and aluminum busbars for electrical applications, as well as fabricating alloys for aerospace, HVAC, and custom metal art.

- General Repair and Maintenance: An essential tool for maintenance shops, welding workshops, and any facility needing a reliable method for joining metal bars and profiles.