Key Differences

The primary differences between the two models are:

- Rated Capacity: The DN3-40KW has a higher rated capacity of 40 KVA compared to the DN3-25KW’s 25 KVA. This indicates the DN3-40KW can deliver more power for welding.

- Rated Primary Current: Corresponding to its higher capacity, the DN3-40KW draws a higher rated primary current of 105A compared to the DN3-25KW’s 65A.

- No Load Voltage: The DN3-40KW has a slightly higher maximum no-load voltage range (0.5-3.58V) than the DN3-25KW (0.5-3.2V).

- Welding Thickness (Low Carbon Steel): The DN3-40KW can weld thicker low carbon steel (2.5+2.5mm) than the DN3-25KW (2+2mm). This is a direct benefit of its higher power output.

Similarities

Both models share several identical specifications, indicating common design elements and features:

- Primary Voltage: Both operate on a 380V primary voltage.

- Rated Frequency: Both are designed for a 50HZ rated frequency.

- Rated Load Duration: Both have a rated load duration of 20%, indicating the proportion of time they can operate under load in a given cycle.

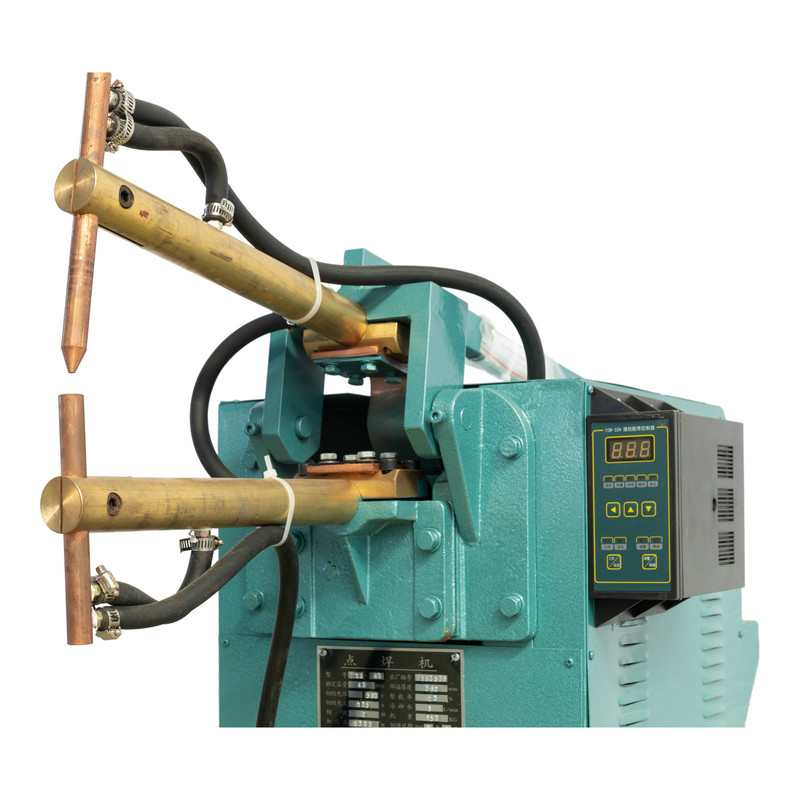

- Extension Length of Electrode Arm: Both have an electrode arm extension length of 300mm.

- Distance Between Electrode Arms: The distance between electrode arms is 200mm for both.

- Working Stroke of Upper Electrode: Both models have a working stroke of 40mm for the upper electrode.

- Maximum Pressure Between Electrodes: Both can apply a maximum pressure of 1000N between electrodes.

- Electrode Arm Diameter: Both utilize electrode arms with a diameter of Ф40mm.

- Electrode Holder Diameter: Both have electrode holders with a diameter of Ф20mm.

- Electrode Head Diameter: Both use electrode heads with a diameter of Ф13mm.

- Adjusting Series: Both models feature stepless voltage regulation, providing fine control over the welding parameters.

The DN3-40KW is a more powerful version of the DN3-25KW, capable of handling thicker materials due to its increased rated capacity and primary current. Otherwise, many of their mechanical and operational specifications are identical, suggesting they are part of the same product family with power output being the primary differentiator.