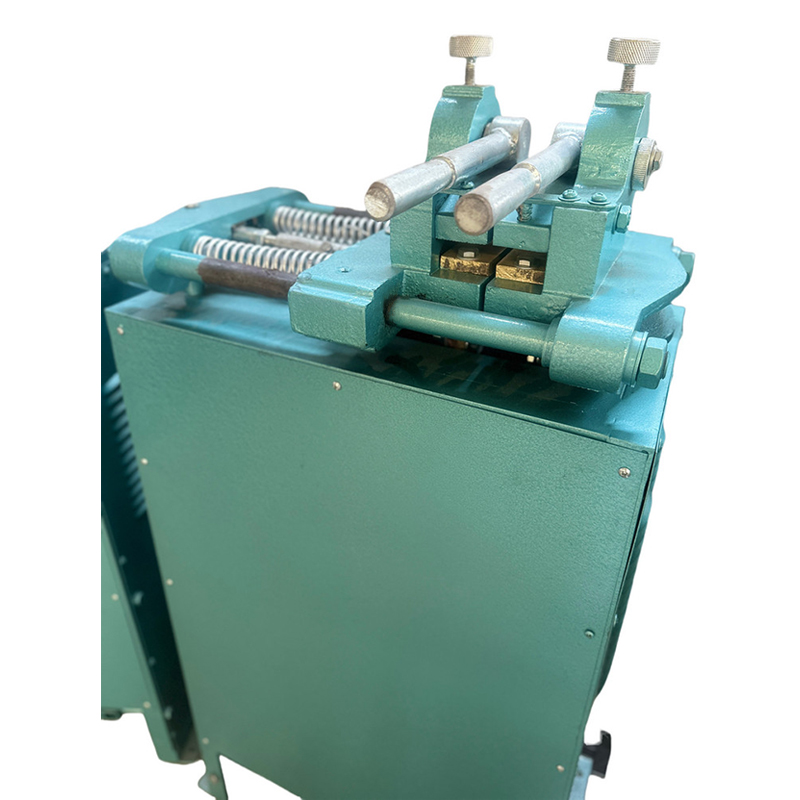

The UN1-100KW Butt Welder is a robust and reliable industrial-grade machine engineered for high-performance resistance butt welding. Designed for simplicity and durability, it delivers consistent, high-quality welds on a wide range of ferrous and non-ferrous materials. Its user-centric design prioritizes operational stability and ease of maintenance, making it an indispensable asset for workshops and production lines demanding efficiency and dependability.

Key Advantages

- Exceptional Welding Quality: Produces strong, clean, and uniform butt welds with excellent metallurgical properties, ensuring joint integrity that often exceeds the strength of the base materials.

- Unmatched Reliability & Stability: The proven AC contactor-controlled main switching circuit guarantees consistent performance weld after weld, minimizing downtime and rejects.

- Remarkably Easy to Maintain: Designed with serviceability in mind. Its straightforward architecture and accessible components significantly reduce maintenance time and costs, maximizing your operational uptime.

- Robust Industrial Construction: Built with a heavy-duty steel frame and high-quality components to withstand the rigors of a demanding industrial environment, ensuring long-term durability.

- Dual Voltage Compatibility: Configured to operate on both 220V and 380V power supplies, offering flexibility for various workshop setups and electrical infrastructures.

Product Features

- High-Capacity Welding Transformer: The heart of the machine, providing the stable and powerful electrical output required for 100KW welding operations on thick steel bars and non-ferrous metals.

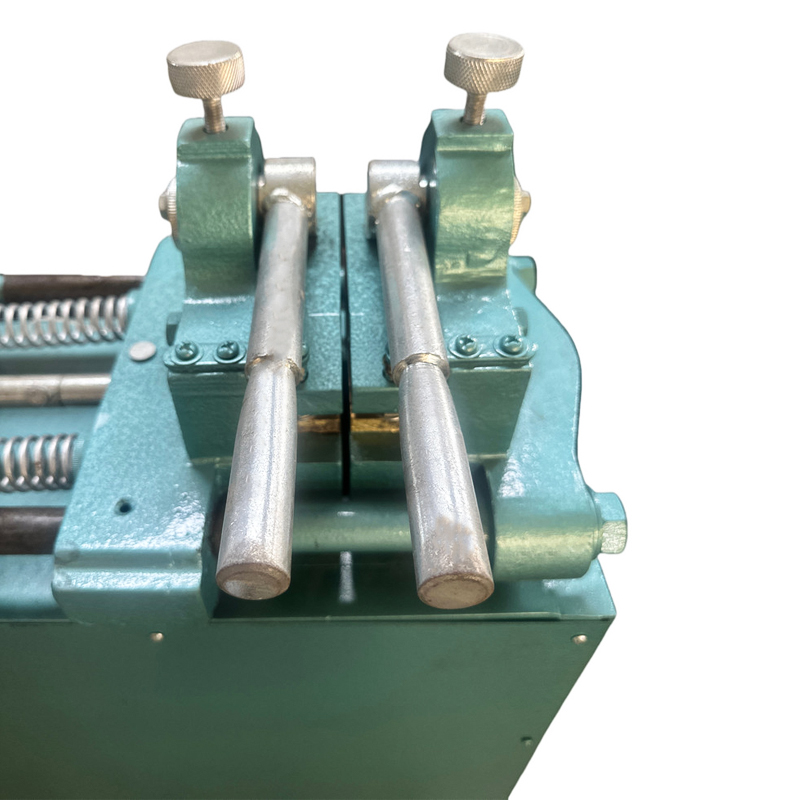

- Precision Electrode System: Features a stationary electrode and a movable electrode (clamp) that securely holds workpieces and ensures perfect alignment for a flawless weld.

- Integrated Pressure-Fed Mechanism: Applies consistent and controlled forging pressure during the welding cycle, which is critical for achieving a dense, void-free weld nugget.

- Simple Control System: Utilizes a reliable AC Contactor for the main circuit, offering a robust and easily serviceable control solution compared to more complex and fragile electronic systems.

- Durable Steel Construction: The entire assembly is housed within a rugged steel frame, protecting internal components and providing stability during operation.

Product Applications

This versatile butt welder is an ideal solution across diverse industries that require strong, permanent metal-to-metal joints:

- Construction & Reinforcement: Ideal for welding low carbon steel rebar and steel bars for concrete reinforcement cages, frames, and mesh.

- Metal Fabrication & Workshops: Perfect for joining metal bars, rods, and profiles used in fencing, grating, furniture, and structural frameworks.

- Automotive & Aerospace: Suitable for welding components made from specific non-ferrous alloys.

- Electrical Industry: Excellently suited for butt welding copper and aluminum wires, busbars, and cables.

- General Manufacturing: A go-to machine for any application involving the end-to-end joining of low carbon steel, copper, aluminum, and their respective alloys.