The UN2-35KW is a high-performance, pneumatic butt welding machine designed for efficiency, precision, and reliability in industrial welding applications. It is engineered to seamlessly join a variety of metals, including low carbon steel, copper, and aluminum, with exceptional consistency.

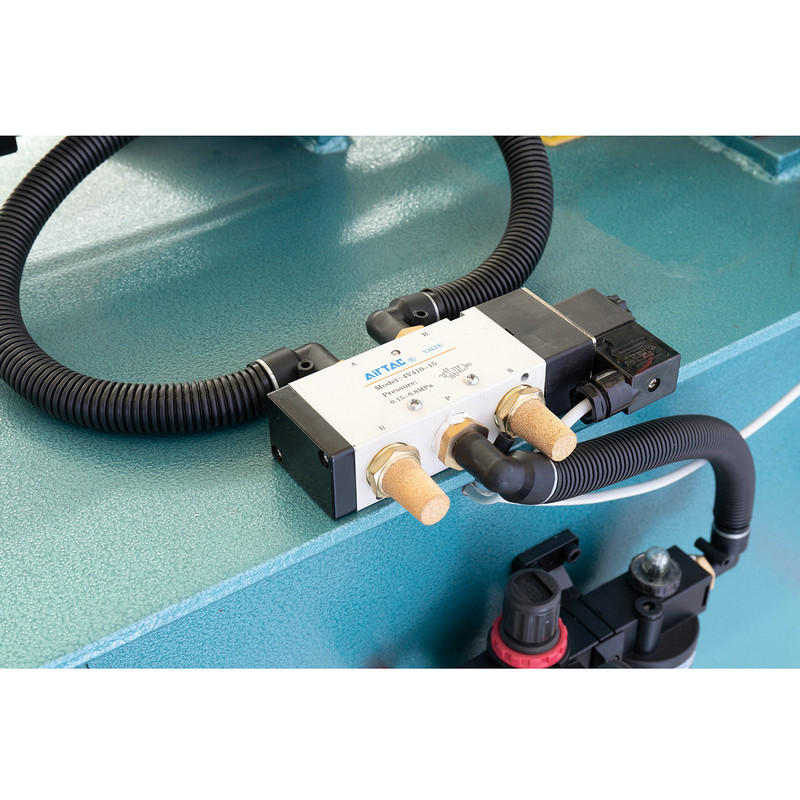

This machine utilizes advanced pneumatic pressure to tighten workpieces, ensuring a stable and firm hold throughout the welding process. The moving clamp is equipped with precision linear bearings, which guarantee exceptionally smooth electrode movement and perfect alignment for accurate, high-quality welds every time.

A key feature of the UN2-35KW is its integrated operational sequence, where clamping, upsetting, and welding are completed in a single, automated step. This streamlined process significantly boosts productivity and reduces operator intervention.

At its core, the welding machine employs a sophisticated Microcomputer Constant Voltage Control System and Two-Stage Discharge technology. This ensures optimal energy delivery for a clean, strong weld. Combined with its robust construction and precision linear bearings (which ensure zero wear on moving parts), the UN2-35KW is built to deliver lasting performance and adapt to a wide range of demanding construction and workshop environments.

Operating Instructions

1. Pre-Operation Setup & Safety Check

- Ensure the machine is connected to a proper 380V power source and a clean, dry compressed air supply.

- Verify that the work area is clean, dry, and free of flammable materials.

- Perform a visual inspection of the cables, electrodes, and pneumatic lines for any signs of damage.

- Confirm that the machine is properly grounded.

2. Machine Preparation

- Power on the machine and the microcomputer control system.

- Adjust the air pressure to the required level to achieve the desired clamping force.

- Set the welding parameters (voltage, discharge time, upsetting force) on the microcomputer controller according to the material type and thickness being welded. Refer to the technical specifications for material capacity limits.

3. Workpiece Preparation & Loading

- Ensure the ends of the workpieces to be welded are clean, flat, and free from contaminants like oil, paint, or oxidation.

- Insert the workpieces into the stationary and moving clamps. The maximum jaw distance is 10mm.

4. Execution of Weld Cycle

- Initiate the weld cycle. The machine will automatically perform the following steps:

- Clamping: The pneumatic system will activate, firmly and stably gripping both workpieces.

- Welding & Upsetting: The moving clamp will advance smoothly on its linear bearings. The microcomputer system will deliver the precise two-stage electrical discharge to heat the materials, immediately followed by an upsetting force (max 10 kN) to forge the pieces together.

- The entire process is completed in one step.

5. Completion

- After the cycle is complete, the clamps will retract.

- Carefully remove the welded assembly (it may be hot).

- Inspect the weld for quality and consistency.

6. Shutdown

- After completing all welding tasks, power down the control system and disconnect the main power supply.

- Clean the machine electrodes and work area.

Note: Always consult the full manufacturer’s manual for detailed safety procedures, maintenance schedules, and troubleshooting guides before operating the equipment.