The UN2-125KW is a high-performance, industrial-grade pneumatic butt welding machine engineered for robust performance and exceptional versatility in demanding construction and fabrication environments. It combines powerful pneumatic clamping with sophisticated microcomputer control to deliver precise, reliable, and efficient welds on a variety of materials.

Key Features & Benefits:

- Strong Pneumatic Clamping: Securely clamps workpieces with consistent pneumatic pressure, ensuring absolute stability and firmness throughout the welding process, which is critical for high-quality welds.

- Precision Movement & Zero Wear: The moving clamp mechanism is equipped with precision linear bearings, enabling seamless electrode movement and accurate positioning. This innovative design guarantees zero wear over time, ensuring long-term accuracy and reducing maintenance.

- Efficient One-Step Operation: Our innovative design allows for clamping, upsetting, and welding to be executed in a single, efficient step, significantly boosting productivity and streamlining the workflow.

- Advanced Microcomputer Control: Features a sophisticated constant voltage system that is microcomputer-controlled. This, coupled with a two-stage discharge process, ensures optimal weld quality and repeatability every time.

- Exceptional Material Adaptability: Highly adaptable to diverse projects, capable of welding low carbon steel (6.0-16.0mm), copper (6.0-12.0mm), and aluminum (6.0-12.0mm).

- Stepless Voltage Regulation: The secondary voltage regulation offers stepless (infinite) adjustment stages (0.8-8.1V), providing unparalleled control for fine-tuning the welding parameters to match the exact job requirements.

Operating Instructions & Guidelines

1. Safety Precautions

- Electrical Safety: Ensure the machine is properly grounded and connected to a 380V power supply that matches the rated capacity. Only qualified personnel should perform electrical connections.

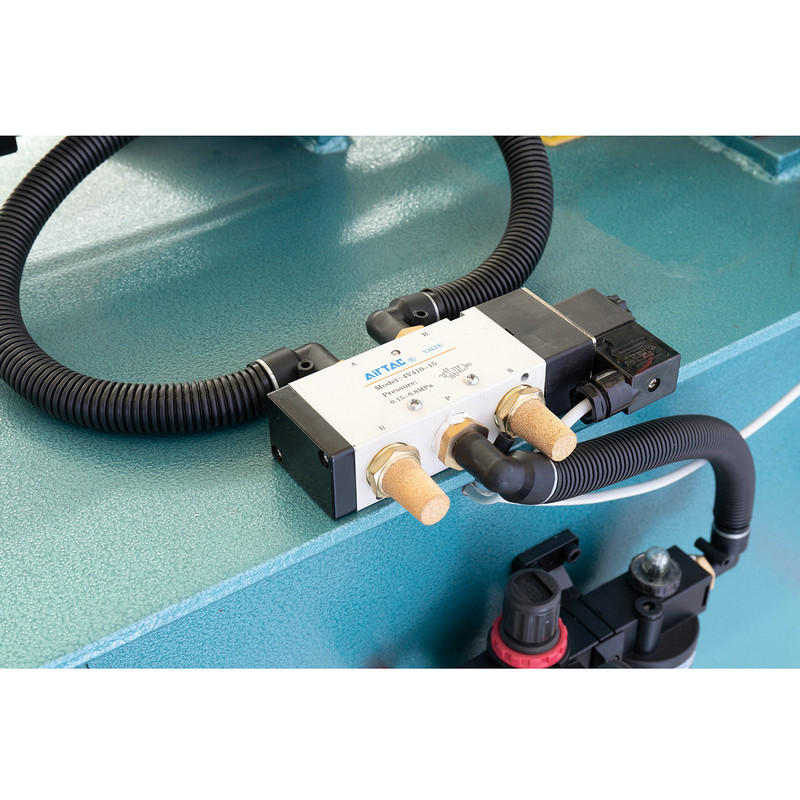

- Pneumatic Safety: Check all air lines and connections for leaks before operation. Ensure the air pressure is set according to the material being welded.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, welding gloves, and flame-resistant clothing.

- Workspace: Keep the work area clean, dry, and free of flammable materials.

2. Pre-Operation Setup

- Inspection: Visually inspect the machine for any signs of damage, loose components, or worn electrodes.

- Power & Air: Connect the machine to the 380V power source and a clean, dry compressed air supply.

- Material Preparation: Prepare the workpieces by cleaning the surfaces to be welded to remove dirt, oil, paint, or oxidation. This is critical for a strong weld.

- Parameter Selection: Based on the material type and diameter (refer to the capacity chart: 6-16mm for steel, 6-12mm for Cu/Al), set the microcomputer controls. Adjust the voltage steplessly via the control panel and set the upsetting force and feeding stroke as required.

3. Operating Procedure

- Position: Place the cleaned workpieces into the machine’s jaws, ensuring they are aligned correctly.

- Clamp: Initiate the pneumatic clamping system. The machine will securely clamp the workpieces, ensuring stability.

- Weld: Initiate the welding cycle. The microcomputer will automatically manage the two-stage discharge process (pre-heat and upsetting).

- Complete Cycle: The machine will complete the entire process—clamping, upsetting, and welding—in one efficient step. The linear bearings ensure smooth, precise movement throughout.

- Unclamp: Once the cycle is complete and the weld has cooled slightly, release the clamps and remove the welded workpiece.

4. Post-Operation & Maintenance

- After use, power down the machine and disconnect it from the main power supply.

- Release any residual air pressure from the pneumatic system.

- Regularly clean the electrodes and moving parts to prevent buildup of spatter and debris.

- Periodically check the linear bearings and moving mechanisms for smooth operation; lubricate as recommended by the manufacturer.

- Store the machine in a clean, dry environment.

Note: Always consult the full manufacturer’s manual for detailed maintenance schedules and specific safety warnings. These instructions are a general guide for qualified operators.