The UN2-100KW is a state-of-the-art, high-performance pneumatic butt welding machine engineered for industrial-grade reliability and exceptional productivity. Designed with a robust metal shell, it is the ideal solution for secure and stable welding of a variety of metals in demanding construction and fabrication settings.

Key Features & Benefits:

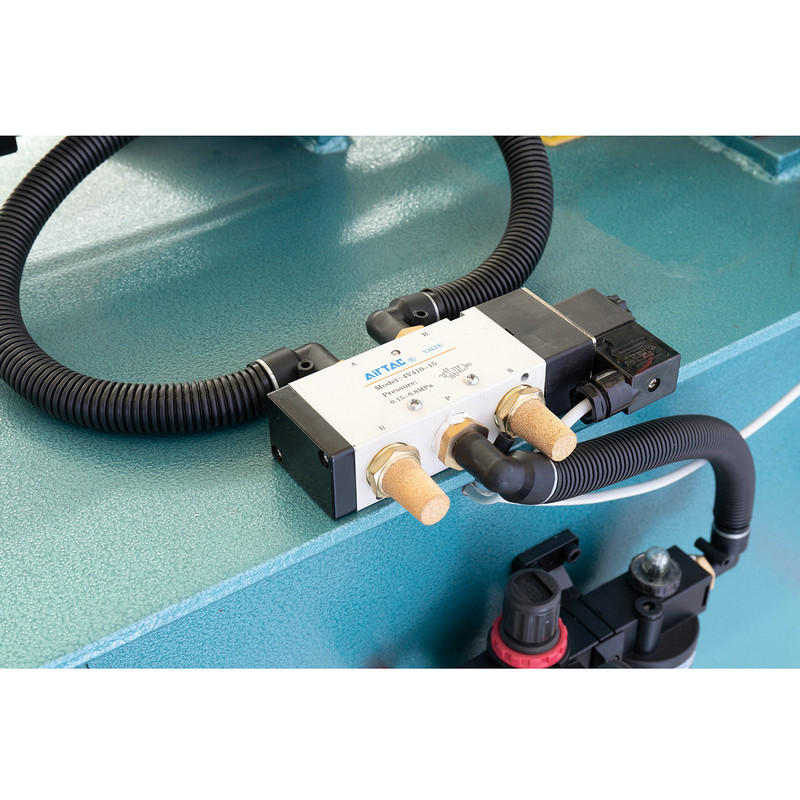

- Pneumatic Clamping System: Harnesses precise pneumatic pressure for secure and vibration-free clamping of workpieces, ensuring perfect alignment and consistent weld quality.

- Microcomputer-Controlled Constant Voltage & Two-Stage Discharge: This intelligent system provides superior control over the welding process, enhancing adaptability to various material types and thicknesses. It ensures optimal energy delivery for a perfect weld every time.

- Zero-Wear Linear Bearing System: The moving clamp utilizes precision linear bearings, guaranteeing smooth electrode movement and flawless alignment. This innovative design eliminates mechanical wear on critical components, ensuring long-lasting performance, reliability, and minimal maintenance.

- Unmatched Efficiency: The integrated design allows for clamping, upsetting, and welding to be executed in a single, automated step, significantly boosting operational productivity and reducing cycle times.

- Versatile Material Application: Capable of welding low carbon steel (5.0-12.0mm), copper (4.0-8.0mm), and aluminum (4.0-8.0mm), making it a highly adaptable tool for various projects.

Operating Instructions

1. Safety Precautions

- Electrical Safety: Ensure the machine is properly grounded and connected to a 380V power supply that matches the rated capacity. Only qualified personnel should perform electrical connections.

- Pneumatic Safety: Connect the machine to a clean, dry air supply at the recommended pressure. Check for pneumatic leaks before operation.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, heat-resistant gloves, and protective clothing to guard against sparks and heat.

- Workspace: Operate in a clean, dry environment free from flammable materials.

2. Setup & Preparation

- Power On: Connect the machine to the 380V power source and the pneumatic air line.

- Material Selection: Select the appropriate jaws and settings based on the material type (low carbon steel, copper, aluminum) and thickness (refer to the capacity specifications).

- Voltage Setting: Use the stepless voltage regulation dial to set the no-load voltage (0.8-7.6V) according to the material thickness and type. Consult the weld settings chart for recommended starting points.

3. Operation Procedure

- Step 1: Clamping. Place the workpieces securely into the stationary and moving clamps. Activate the pneumatic system to clamp the workpieces with stable and even pressure.

- Step 2: Alignment. The linear bearing system will ensure the moving clamp and electrode advance smoothly for precise alignment. Visually confirm the workpieces are butted together correctly.

- Step 3: Welding. Initiate the weld cycle. The microcomputer control will automatically manage the two-stage discharge process, applying the correct current and followed by the upsetting force.

- Step 4: Upsetting & Completion. The machine will apply the programmed upsetting force (up to 1000N) to forge the weld joint. The cycle will complete automatically. Release the pneumatic clamps and remove the welded workpiece.

4. Maintenance

- Regular Inspection: Periodically inspect the clamping jaws for wear and the linear bearings for smooth operation. The zero-wear design minimizes but does not eliminate the need for checks.

- Cleaning: Keep the machine clean and free from dust, metal shavings, and moisture.

- Pneumatic System: Regularly drain moisture from the air filter regulator and check for leaks.

Note: Always refer to the full manufacturer’s manual provided with the machine for detailed wiring diagrams, troubleshooting guides, and specific maintenance schedules.