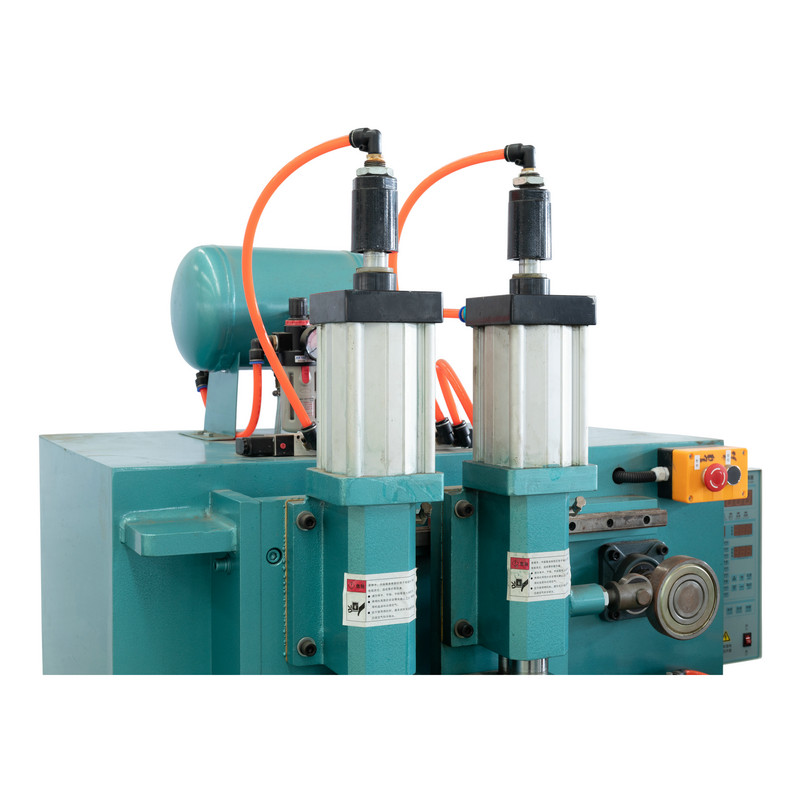

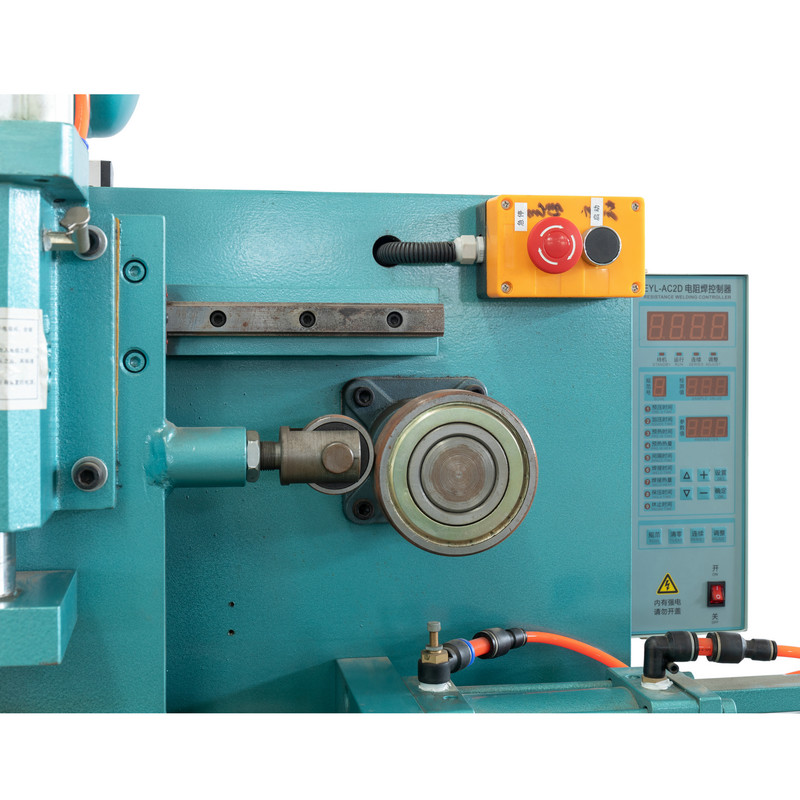

The UN3-200KW Metal Shell Pipe Flash Butt Welding Machine is a high-performance, precision-engineered solution designed for robust and reliable flash butt welding. Encased in a durable metal shell, this machine integrates advanced microcomputer control technology to automate and perfect the entire welding sequence—clamping, flashing, upsetting, connecting, and stopping.

This automated process ensures consistently superior welded products characterized by exceptionally high strength, impeccable density, and a flawless finish. The welds are free from common defects such as false welding, slag inclusions, and pores, resulting in joints that are not only structurally sound but also aesthetically pleasing.

Operating Instructions

1. Pre-Operation Safety & Setup Checklist

- Power Verification: Ensure your power supply matches the machine’s requirement of 380V/50Hz. The electrical connection must be performed by a qualified electrician.

- Inspection: Visually inspect the machine, cables, and clamps for any signs of damage or wear before operation.

- Securing the Workpiece: The work area must be clean. Securely mount the workpiece to be welded in the machine’s jaws, ensuring it is properly aligned and within the machine’s capacity (max diameter: Ф40mm steel pipe).

- Cooling System: Verify that the machine’s cooling system is functional and filled (if applicable) to prevent overheating during the duty cycle.

2. Microcomputer Controller Setup

- Power on the machine and the microcomputer controller.

- Using the control interface, input or select the welding parameters suitable for your specific material type (e.g., round steel, square tube) and cross-sectional area. The stepless voltage regulation allows for fine-tuned adjustments.

- The controller will store these parameters for executing the personalized welding cycle.

3. Executing the Welding Cycle

Initiate the process. The microcomputer controller will automatically execute the following sequence:

- Clamping: The jaws close with a force of up to 8000N to securely grip the workpieces without movement.

- Flashing: The controller applies power, creating an arc that heats the ends of the materials to a plastic state through a controlled burn-off.

- Upsetting: Once the optimal temperature is reached, the machine forces the plasticized ends together with a high upsetting force (up to 3000N), expelling impurities and creating a solid-state weld.

- Connecting & Stopping: The weld is consolidated and held briefly. The cycle completes automatically, and power is cut.

4. Post-Operation

- Carefully remove the welded product.

- Inspect the weld for the expected high-quality appearance and strength.

- Power down the machine and keep the work area clean.

Important Note: Always adhere to the machine’s 20% rated load duration to avoid overheating. This means the machine should be active for 2 minutes followed by an 8-minute cooling period for every 10-minute cycle. Never exceed the maximum specified clamping and upsetting forces.