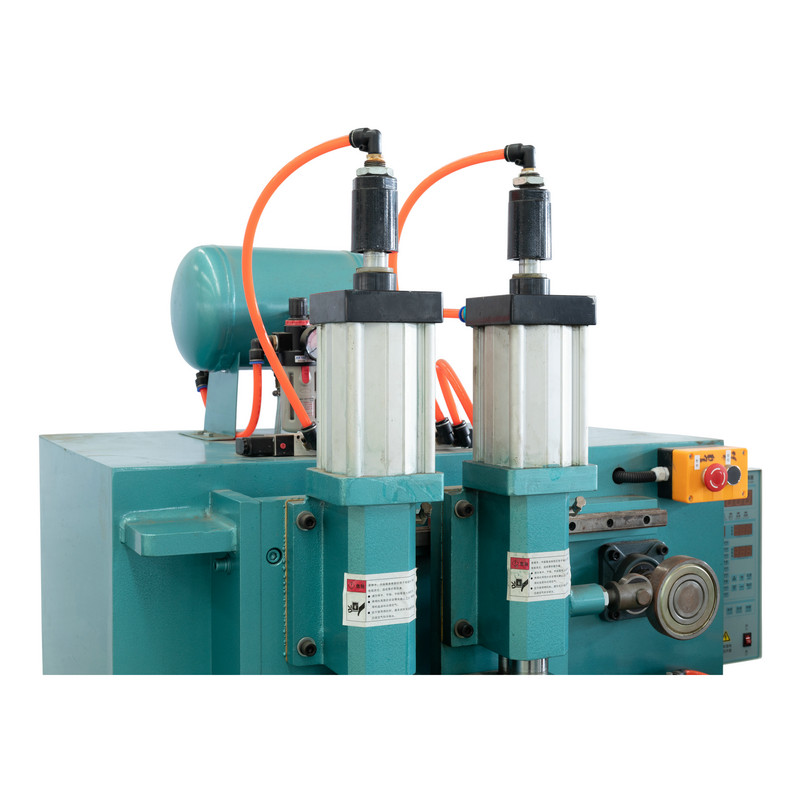

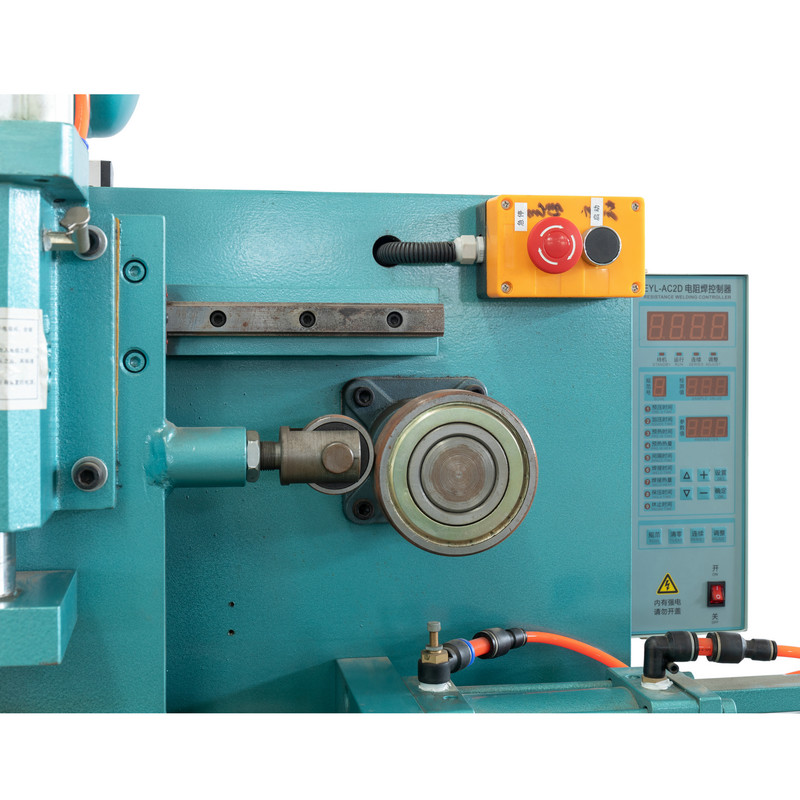

The UN3-150KW is a state-of-the-art flash butt welding machine engineered for industrial-grade performance and exceptional weld integrity. Equipped with an advanced microcomputer controller, it automates and precisely executes the entire welding sequence—including clamping, flashing, upsetting, connection, and termination. This ensures consistent, high-quality results with every operation.

The welded products produced by the UN3-150KW are renowned for their remarkable strength and density. They are completely free from common defects such as false welding, slag inclusions, and pores, resulting in joints that are not only structurally sturdy but also aesthetically pleasing.

This versatile machine is the ideal solution for butt welding a diverse array of hardware and metal profiles, including:

- Round and Square Tubes

- Round Steel and Rebar

- Flat Iron and Steel Strips

- Bicycle and Motorcycle Rims

- And other similar components.

Operating Instructions

1. Safety Precautions

- Qualified Personnel: Only trained and authorized personnel should operate this machine.

- Power Supply: Ensure the machine is connected to a proper 380V/50Hz power source with a reliable grounding system.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, welding gloves, and flame-resistant clothing.

- Machine Inspection: Before operation, visually inspect the machine for any loose connections, damaged cables, or hydraulic leaks.

2. Setup & Preparation

- Workpiece Preparation: Clean the ends of the workpieces to be welded. Remove any rust, paint, oil, or debris to ensure optimal conductivity and weld quality.

- Jaw Adjustment: Adjust the jaws according to the size and shape of your workpiece, ensuring it is securely held. Do not exceed the maximum jaw distance of 40mm.

- Parameter Selection: On the microcomputer controller, select the appropriate program or set the parameters (flashing time, upsetting force, etc.) for the specific material type and cross-sectional area. Do not exceed the machine’s maximum welding capacity (Ф25mm steel pipe).

3. Welding Operation

- Clamping: Securely clamp both workpieces in the jaws. The high clamping force (max 8000N) prevents slippage during the process.

- Initiation: Start the automated welding cycle via the controller. The machine will sequentially perform:

- Flashing: The ends of the workpieces are brought together, creating a controlled arc that heats the metal to forging temperature.

- Upsetting: Once the optimal temperature is reached, the machine applies a high upsetting force (max 3000N) to forge the molten ends together, expelling impurities and creating a solid-state bond.

- Termination: The cycle completes automatically.

- Monitoring: Observe the process. The flash should be consistent and steady.

4. Post-Operation

- Unclamp: Carefully remove the finished welded assembly. The workpiece will be very hot—handle with tongs.

- Inspection: Check the weld bead for consistency and a clean, finished appearance.

- Maintenance: Keep the machine clean and well-lubricated according to the manufacturer’s maintenance schedule. Regularly check the alignment of the jaws and electrodes.

Note: For detailed maintenance schedules and troubleshooting, always refer to the full user manual provided with the machine.