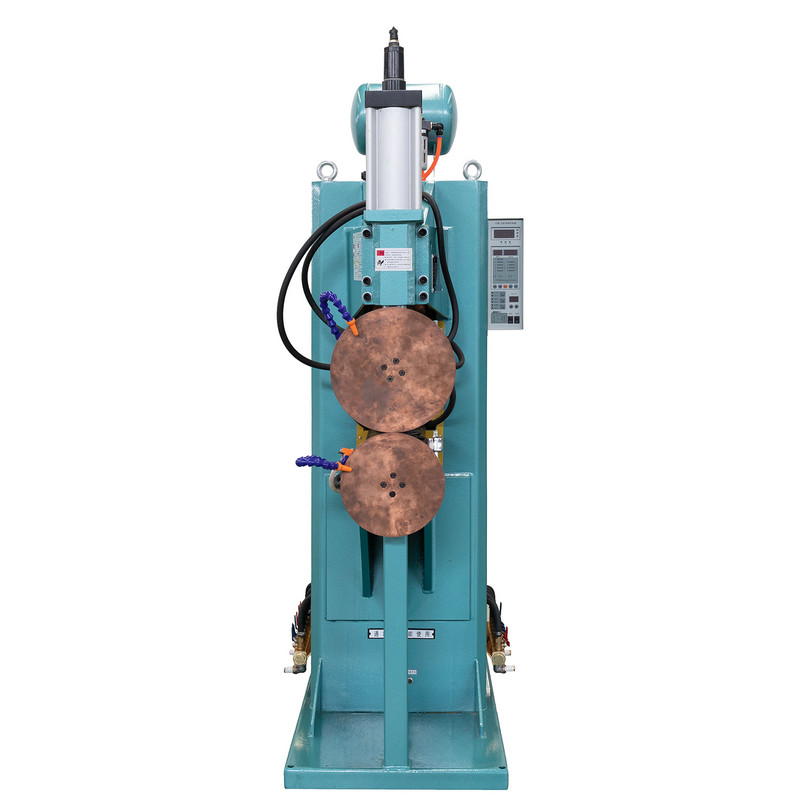

The FN-100 Circumferential Seam Welding Pneumatic Seam Welder is engineered for precision welding of metal joints requiring sealing, as well as standard sheet metal components. It accommodates metal thicknesses from 0.1mm to 2.5mm and offers reliable performance for diverse industrial applications. Equipped with a three-phase stepless speed regulation drive, the machine ensures convenient and stable welding speed adjustments. Its flexible design supports both vertical and horizontal welding configurations, making it suitable for a wide range of box-shaped workpieces.

Detailed Description

-

Versatile Application:

Suitable for circumferential seam welding of sealed joints and general sheet metal welding, meeting diverse production needs.

-

Material Compatibility:

Efficiently welds metal sheets with thickness ranging from 0.1mm to 2.5mm, covering a broad spectrum of industrial materials.

-

Stepless Speed Control:

Features a three-phase stepless speed regulation drive, allowing precise and stable adjustment of welding speeds, improving welding quality and consistency.

-

Flexible Welding Orientation:

Supports both vertical and horizontal welding, accommodating various shapes and sizes of box-like workpieces.

-

Durable Pneumatic System:

Integrated pneumatic welding mechanism ensures reliable seam formation and consistent joint integrity across repetitive production cycles.

-

Enhanced Production Efficiency:

Designed to streamline welding processes, reducing setup time and enhancing overall workflow efficiency.

FAQ

Q1: What thickness of metal can the FN-100 weld?

A1: It can weld metal sheets ranging from 0.1mm to 2.5mm.

Q2: Can the FN-100 weld non-sealed sheet metal?

A2: Yes, it is suitable for both sealed joints and standard sheet metal welding.

Q3: Does the machine allow speed adjustments during welding?

A3: Yes, the three-phase stepless speed regulation drive enables precise and stable speed adjustments.

Q4: What welding orientations are supported?

A4: The FN-100 can operate in both vertical and horizontal positions, providing flexibility for various workpiece designs.

Q5: Is the machine suitable for box-shaped workpieces?

A5: Yes, its design accommodates box-shaped and other complex workpieces, ensuring uniform seam quality.