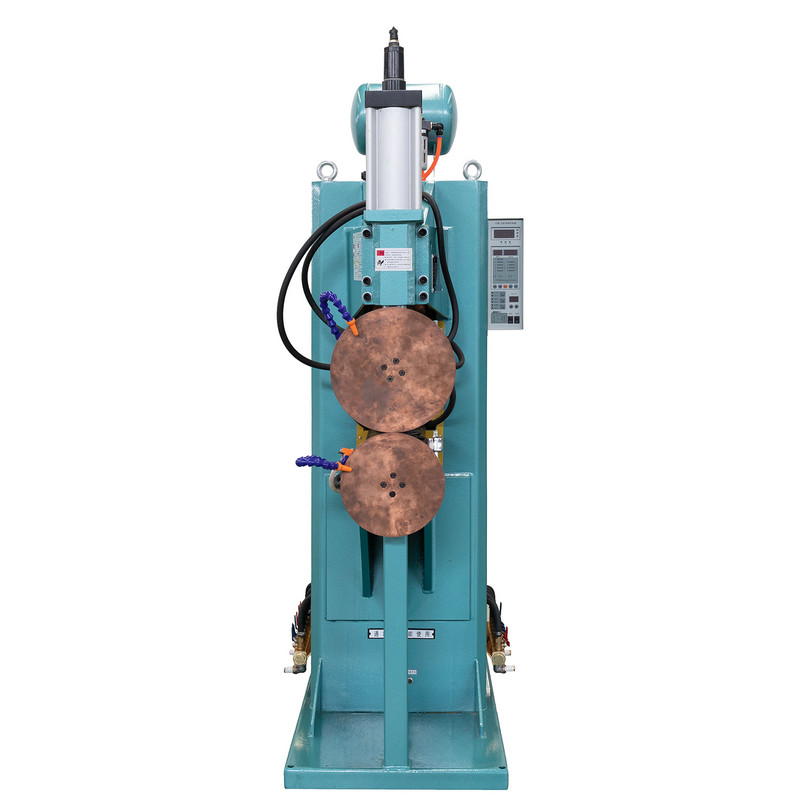

The FN-150 Transverse/Longitudinal Seam Customizable Pneumatic Seam Welder is engineered for precision and versatility in metal fabrication. It is widely used for welding joints requiring sealing and is equally effective for standard sheet metal components that do not need sealing. Designed to handle metal materials with thicknesses ranging from 0.1mm to 2.5mm, this machine ensures consistent, high-quality welding performance. Its adaptable welding configurations, supporting both vertical and horizontal setups, make it suitable for box-shaped and irregular workpieces.

Detailed Description

Key Features and Advantages:

- Customizable Welding Modes: Supports transverse and longitudinal seam welding, allowing operators to tailor processes to specific production requirements.

- Material Compatibility: Efficiently welds metal sheets from 0.1mm to 2.5mm in thickness, covering a wide range of fabrication needs.

- Three-Phase Stepless Speed Control: Equipped with a three-phase stepless speed control drive, providing smooth, precise, and stable adjustments to welding speed.

- Versatile Orientation: Can operate in vertical or horizontal configurations, offering flexibility to accommodate different shapes and sizes of workpieces.

- Sealing and Non-Sealing Applications: Optimized for both sealing joints and conventional sheet metal welding, increasing its usability across diverse manufacturing scenarios.

- Robust Construction: Built with durable components to withstand continuous operation, ensuring long-term reliability and consistent weld quality.

FAQ

Q1: What types of metal can the FN-150 weld?

A1: The FN-150 is compatible with various metals within the thickness range of 0.1mm to 2.5mm, including standard sheet metals used in industrial fabrication.

Q2: Can this machine weld both sealed and non-sealed joints?

A2: Yes, it is designed for both sealing applications and conventional sheet metal welding, making it highly versatile.

Q3: How is the welding speed controlled?

A3: The machine features a three-phase stepless speed control drive, allowing operators to adjust welding speed easily and maintain consistency throughout production.

Q4: Is the FN-150 suitable for complex-shaped workpieces?

A4: Absolutely. Its vertical and horizontal welding configurations make it adaptable for box-shaped or irregular workpieces.

Q5: What are the main benefits of using the FN-150?

A5: The primary benefits include high-quality welds, versatile application, smooth speed control, and adaptability to diverse workpiece orientations.