1. Introduction

1.1 Basic tools in the welding industry: Why is it important to choose the right welding fixture

In welding work, the choice of tools is directly related to the quality and safety of the work. As an important tool for supporting and fixing welded parts, the performance and stability of welding fixtures are crucial to the welding effect. With the continuous advancement of technology, welding tools are also constantly developing and updating. As an indispensable tool in the welding process, Ф16 Welding Grip's unique design and functions are helping welders to complete their work more efficiently and safely.

1.2 The demand for tools in the welding industry

Welding work often involves dangerous factors such as high temperature, high pressure and flammable materials, requiring tools to be able to operate efficiently in these harsh environments. Welding fixtures not only need to provide stable support, but also need to have a certain degree of flexibility and adjustability. Ф16 Welding Grip has shown unique advantages in meeting these needs.

1.3 Purpose and structure of this article

This article will explore the background, role and importance of Ф16 Welding Grip in the welding industry, focusing on how it has become an indispensable tool in welding work by improving stability, precision and efficiency.

2. Overview of Ф16 Welding Grip

2.1 What is Ф16 Welding Grip?

The Ф16 Welding Grip is a tool used to fix welding workpieces. It is mainly used to firmly clamp the workpiece in a specific position during the welding process. Its simple design but powerful function can help welders ensure that the workpiece remains stable under high temperature and pressure, avoiding displacement or deformation, thereby improving the accuracy and quality of welding.

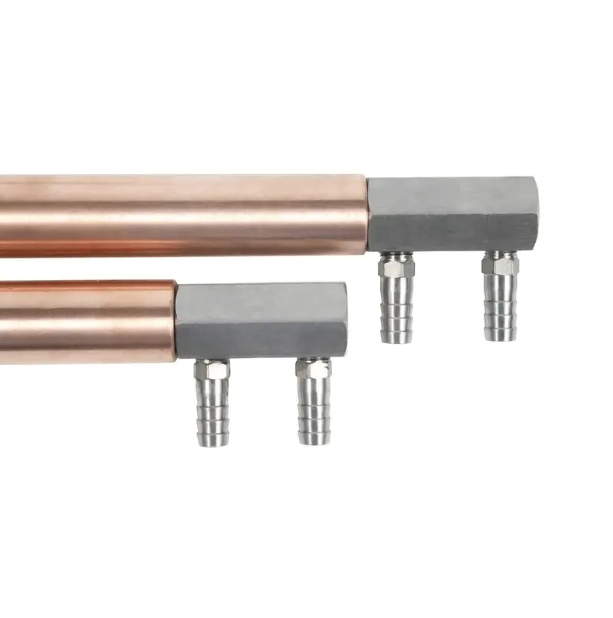

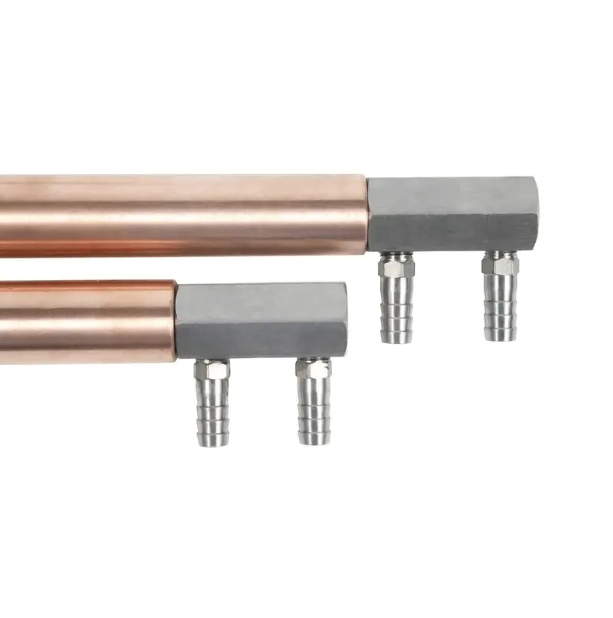

2.2 Structure and function of Ф16 Welding Grip

The Ф16 Welding Grip is usually made of high-strength metal and has the characteristics of high temperature resistance and corrosion resistance. Its structural design includes a clamping part, an adjustment device and a fixed base to ensure stable operation in various working environments. Compared with other types of clamps, Ф16 Welding Grip is usually more delicate and can provide more uniform clamping force to avoid excessive pressure or uneven clamping force on the workpiece.

2.3 Historical background and development of Ф16 Welding Grip

Welding clamps have a long history of use. With the continuous advancement of welding technology, the types and functions of clamps have also been continuously developed. As an important tool in the welding industry, Ф16 Welding Grip originated in the mid-20th century. After continuous improvement, it has now become one of the mainstream tools widely used in different welding occasions.

3. The role and advantages of Ф16 Welding Grip

3.1 Improve welding stability and accuracy

During the welding process, the stability of the workpiece is the key to ensuring the quality of welding. Ф16 Welding Grip ensures that the workpiece will not shift or deform during the entire welding process through its precise clamping function, thereby significantly improving the accuracy of welding. Stable workpiece fixation can avoid uneven joints and welding defects caused by workpiece displacement.

3.2 Optimize the efficiency of the welding process

Welders often need to frequently adjust and fix the workpiece. Traditional welding fixtures often take a long time to adjust and fix in this process. The design of the Ф16 Welding Grip makes the fixing process simpler and faster, significantly improving work efficiency. By quickly fixing the workpiece, welders can reduce the preparation time before welding and focus more on the welding operation itself, further improving work efficiency.

3.3 Improve operational safety

The high temperature and current involved in welding operations often pose potential safety hazards to operators. The Ф16 Welding Grip can ensure that the workpiece is firmly clamped, thereby reducing safety accidents caused by workpiece sliding or instability. In addition, stable clamping also reduces unexpected risks during welding, further improving the safety of the working environment.

4. Application areas of the Ф16 Welding Grip

4.1 Widely used in various welding occasions

The Ф16 Welding Grip is very adaptable and can be used in light to heavy welding work. Whether it is precision welding or welding of large structures, the Ф16 Welding Grip can provide stable support. Especially in complex welding tasks, it can provide precise clamping to keep the workpiece in the best welding state.

4.2 Used for welding of different materials

When welding workpieces of different materials, the flexibility and durability of the Ф16 Welding Grip are particularly important. Whether it is steel, aluminum alloy, or other alloy materials, the Ф16 Welding Grip can ensure the good adaptability and efficient fixation of the fixture to workpieces of different materials through reasonable design and adjustment, avoiding the problem of loose clamping caused by material differences.

4.3 Suitable for manual and automatic welding

Whether it is traditional manual welding or modern automatic welding, the Ф16 Welding Grip can provide great convenience. In manual welding, workers can manually adjust the fixture to accurately control the position of the workpiece; in automatic welding, the Ф16 Welding Grip can quickly and accurately fix it to ensure high efficiency and high precision of welding.

5. How to choose a suitable Ф16 Welding Grip

5.1 Consider the material and structural design

When choosing a suitable Ф16 Welding Grip, you first need to consider its material. High-strength alloy steel, high-temperature resistant and corrosion-resistant materials are usually the best choices. In addition, structural design is also a factor that needs to be considered in the selection process. Reasonable structural design can maximize the stability and adaptability of the clamp.

5.2 Durability and long-term use value

High-quality Ф16 Welding Grip can not only provide stable support during welding, but also maintain its performance and stability in long-term use. Durable clamps can reduce replacement frequency and maintenance costs, saving long-term expenses. Therefore, when choosing, you should pay attention to the durability and long-term value of the clamp.

5.3 Maintenance and care tips

In order to extend the service life of the Ф16 Welding Grip, daily maintenance and care are essential. Regularly check whether the fixed part of the clamp is loose, and ensure that there is no damage such as cracks or corrosion on the surface of the clamp. At the same time, it is also an important measure to store the clamp properly and avoid direct contact with high-temperature objects to extend the service life.

6. Technological innovation and future trends

6.1 Modern technology innovation for welding fixtures

With the development of welding technology, new materials and design concepts are constantly introduced into the production process of welding fixtures. The application of high-strength materials, intelligent fixture design and the addition of automated control systems have greatly improved the performance of fixtures, enabling them to adapt to more complex and demanding welding tasks.

6.2 Intelligent welding fixtures

Future welding fixtures will not only be physical tools, but may have intelligent control functions. Through the introduction of technologies such as sensors and automatic adjustment systems, intelligent welding fixtures can provide real-time feedback on the status of the workpiece, automatically adjust the clamping force, and further improve the accuracy and efficiency of welding.

6.3 Future development direction of Ф16 Welding Grip

With the gradual popularization of intelligent welding systems, Ф16 Welding Grip may also develop in a more efficient and intelligent direction. The future Ф16 Welding Grip may integrate more sensor technologies, and even have automatic adjustment and self-diagnosis functions, greatly improving the automation and intelligence level of welding work.

7. Conclusion

7.1 Summary of the indispensability of Ф16 Welding Grip in the welding industry

The Ф16 Welding Grip has become one of the indispensable tools in the welding industry through its efficient clamping function, excellent stability and safety. In terms of improving welding accuracy, optimizing work efficiency and ensuring operational safety, the Ф16 Welding Grip has demonstrated its important role.

7.2 Outlook on the continuous development and tool innovation of the welding industry

With the continuous advancement of welding technology and equipment, welding fixtures will also develop in a more intelligent and automated direction. In the future, the Ф16 Welding Grip and similar tools will play a greater role in improving productivity, reducing costs and improving welding quality.