1: Hidden Corrosion Risks Threaten Reliability of One-stop Resistance Welding Machines

1.1: Automation Brings Efficiency—But Also Conceals Structural Weaknesses

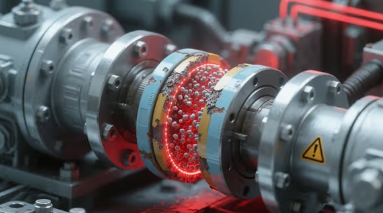

As One-stop Resistance Welding Machines revolutionize modern manufacturing with seamless automation and high-precision integration, their complex structural design introduces vulnerable points often overlooked. Flange connections, gasket seals, and mechanical joints—designed to enhance stability—unintentionally harbor crevices that are susceptible to corrosion under aggressive working environments.

1.2: Chloride Ion Accumulation Turns Gaps into Corrosion Incubators

In humid or chemically aggressive industrial settings, chloride ions from cleaning agents, lubricants, or the atmosphere itself can infiltrate these structural crevices. With poor ventilation and restricted flow inside these narrow spaces, ions accumulate rather than disperse. This creates localized environments where corrosion-inducing agents can concentrate—forming the perfect breeding ground for crevice corrosion to initiate.

1.3: Microscopic Gaps, Macroscopic Risks in Welding System Integrity

While these crevices may be nearly invisible to the naked eye, their consequences are anything but. Once corrosion initiates within these gaps, the damage can remain undetected for long periods—until it compromises the machine’s operational stability. In welding systems where gas sealing, cooling efficiency, and load-bearing integrity are paramount, such hidden corrosion poses serious safety, quality, and maintenance risks.

2: Chloride Ion Attack on Passivation Film Triggers Accelerated Crevice Corrosion

2.1: Stainless Steel’s Defense Fails in Chloride-Saturated Crevices

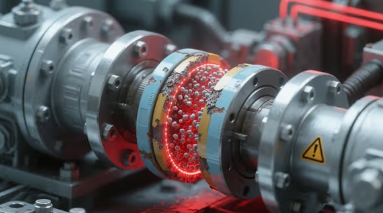

The stainless steel components of resistance welding machines rely on a passive oxide film for corrosion resistance. However, in crevices where chloride ion concentration increases, this protective layer is chemically undermined. The aggressive ions selectively attack micro-defects on the film—such as dislocations and grain boundaries—compromising its stability.

2.2: Localized Film Breakdown Exposes Steel to Unchecked Electrochemical Reactions

Once the passivation film breaks down, the underlying metal is left exposed to a chemically active, oxygen-depleted microenvironment. Here, stainless steel behaves as the anode in an electrochemical cell, accelerating dissolution. The result is not just corrosion, but a rapid and self-sustaining degradation process unique to crevice corrosion mechanisms.

2.3: Invisibility of Initial Damage Masks Deepening Structural Loss

Unlike general surface corrosion, crevice corrosion begins and spreads internally. It forms electrochemical gradients within the confined space, making it difficult to detect via surface inspections. By the time visual signs appear, substantial internal thinning or structural weakness may already have developed, threatening the long-term functionality of the welding system.

3: Corrosion Channels Compromise Structure, Seal, and Safety in Welding Operations

3.1: Progressive Thinning Undermines Mechanical Load-Bearing Capacity

As crevice corrosion evolves, slender corrosion channels extend along the metal grain structure, penetrating deeper into the material. This gradual but relentless material loss reduces the cross-sectional thickness of load-bearing parts such as frames and arms, leading to increased mechanical deformation, potential cracking, and eventual structural failure under operational stress.

3.2: Seal Failure Causes Cooling and Shielding System Malfunctions

The effects of crevice corrosion go beyond mechanical damage. It also disrupts the sealing between components, leading to leakage of shielding gas and cooling fluids. In precision welding, even minor shielding gas loss can result in oxidation, porosity, and weld defects. Likewise, compromised coolant flow exposes internal parts like electrodes and transformers to overheating and thermal degradation.

3.3: Escalating to Catastrophe: Fire, Explosion, and Toxic Hazards

In the worst-case scenario, leaked media such as flammable gases or toxic chemicals pose immediate risks to personnel and facilities. A small crevice-triggered leak can cascade into full-scale safety incidents including fires, explosions, or chemical exposure. Without early detection and intervention, what starts as microscopic corrosion may culminate in major industrial accidents.