The M4-M10 Vibration Plate Feeder Nut Conveyor is designed for efficient, automated transportation of nuts in manufacturing environments such as automotive, shipbuilding, and industrial assembly lines. It works seamlessly with spot welding machines to ensure the standardization of welding timing and quality. The system is engineered to meet the demands of safety, precision, and continuous production efficiency.

Detailed Description

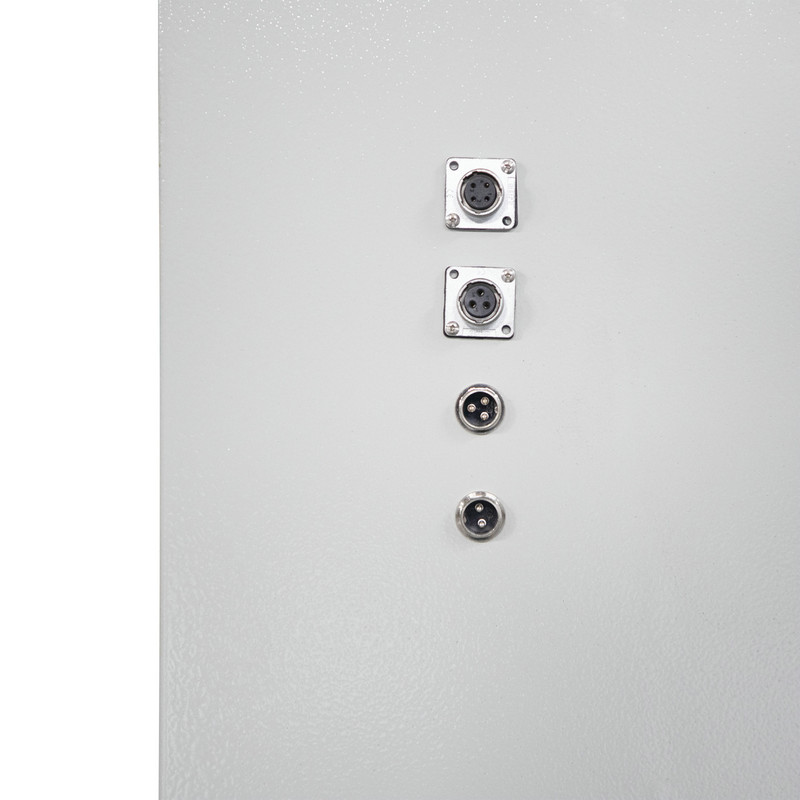

- Core Components: The feeder consists of a vibrating plate, conveying gun, conveying pipe, and control box, providing a compact and reliable nut transportation system.

- Wide Compatibility: Supports nut sizes ranging from M4 to M10, suitable for a variety of spot welding and assembly applications.

- Automated Feeding: Ensures consistent nut supply, reducing manual intervention and improving production efficiency.

- Adjustable Vibration Control: The control box allows precise adjustments of vibration intensity and frequency, ensuring smooth nut movement and accurate positioning.

- Durable Design: Constructed with high-quality materials to withstand continuous operation in industrial environments.

- Enhanced Safety: Designed to meet industrial safety standards, minimizing risk during operation.

- Easy Integration: Can be integrated with existing assembly lines and spot welding systems, optimizing workflow and reducing setup time.

FAQ

Q1: What nut sizes does this conveyor support?

A1: The system accommodates M4 to M10 nuts, making it versatile for multiple industrial applications.

Q2: Can the vibration intensity be adjusted?

A2: Yes, the control box allows fine-tuning of vibration speed and intensity to ensure smooth and precise nut feeding.

Q3: Is this conveyor compatible with spot welding machines?

A3: Absolutely. The conveyor is specifically designed to work with spot welding systems, standardizing welding timing and improving process consistency.

Q4: What materials is the feeder made from?

A4: The feeder is made from durable industrial-grade materials, ensuring long-lasting performance in continuous production environments.

Q5: Can this feeder be easily integrated into an existing assembly line?

A5: Yes, the compact and modular design allows seamless integration with most automated assembly and welding systems.