The M12-M16 Nut and Bolt Conveyor is designed for applications in the automotive industry, shipbuilding, and other manufacturing sectors where precise and reliable nut delivery is critical. This conveyor system works in tandem with spot welding machines, ensuring that the timing and quality of the welding process are standardized. Its robust construction and intelligent design support safety, efficiency, and automation in production lines.

Detailed Description

-

Versatile Material Handling: Capable of conveying M12 to M16 nuts and bolts, this system accommodates a wide range of fasteners commonly used in industrial welding applications.

-

Integrated Vibrating Plate: Ensures consistent feed of nuts and bolts, reducing manual intervention and minimizing production delays.

-

Conveying Gun and Transport Tube: Facilitates precise positioning of fasteners, aligning them accurately with spot welding equipment for enhanced welding quality.

-

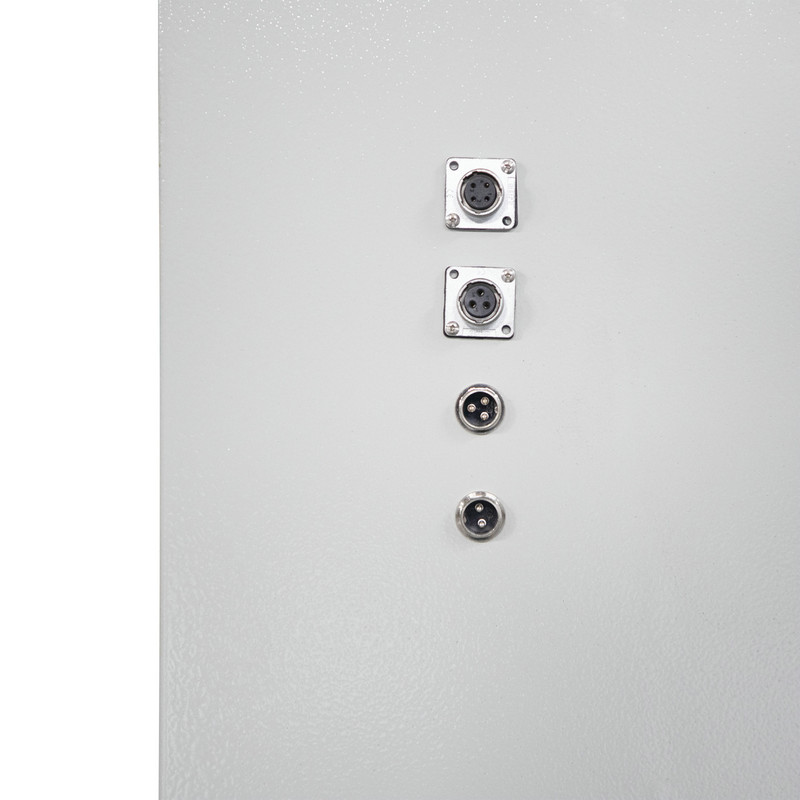

Advanced Control Box: Provides automated operation, adjustable vibration intensity, and monitoring features to maintain stable and efficient production performance.

-

Safety and Efficiency: Designed to meet industrial safety standards while maximizing operational efficiency, the system reduces human error and improves production throughput.

-

Automation-Friendly Design: Easily integrates with existing spot welding machinery, enabling seamless workflow automation and consistent output quality.

FAQ

Q1: What types of fasteners can this conveyor handle?

A1: The system is suitable for M12 to M16 nuts and bolts, making it versatile for standard industrial welding applications.

Q2: Can it be used with all spot welding machines?

A2: Yes, the conveyor is designed to integrate with most spot welding machines, ensuring precise delivery and alignment of fasteners.

Q3: How does the vibrating plate improve performance?

A3: The vibrating plate ensures consistent feeding of nuts and bolts, reducing interruptions and maintaining the timing and quality of the welding process.

Q4: Is the conveyor safe to operate?

A4: Yes, the system is equipped with safety features and an advanced control box to comply with industrial safety standards while minimizing operational risks.

Q5: Can the conveyor system be customized?

A5: Yes, the control parameters and feed mechanisms can be adjusted to suit different production line requirements and fastener types.