The M4-M16 Robot Module is specifically designed for automated nut feeding and assembly processes in industries such as automotive manufacturing, shipbuilding, and heavy machinery production. By integrating seamlessly with robotic arms and spot welding systems, it ensures consistent delivery of M4 to M16 nuts, improving welding accuracy, efficiency, and production safety. The module facilitates a highly automated workflow, minimizing manual intervention while maintaining a reliable and continuous supply of nuts for precision assembly tasks.

Detailed Description

Key Features and Advantages:

- Versatile Nut Compatibility: Supports M4 to M16 nuts, accommodating a wide range of assembly requirements.

- Precision Vibrating Plate: Ensures uniform feeding of nuts to the conveyor system, reducing the risk of jamming or misalignment.

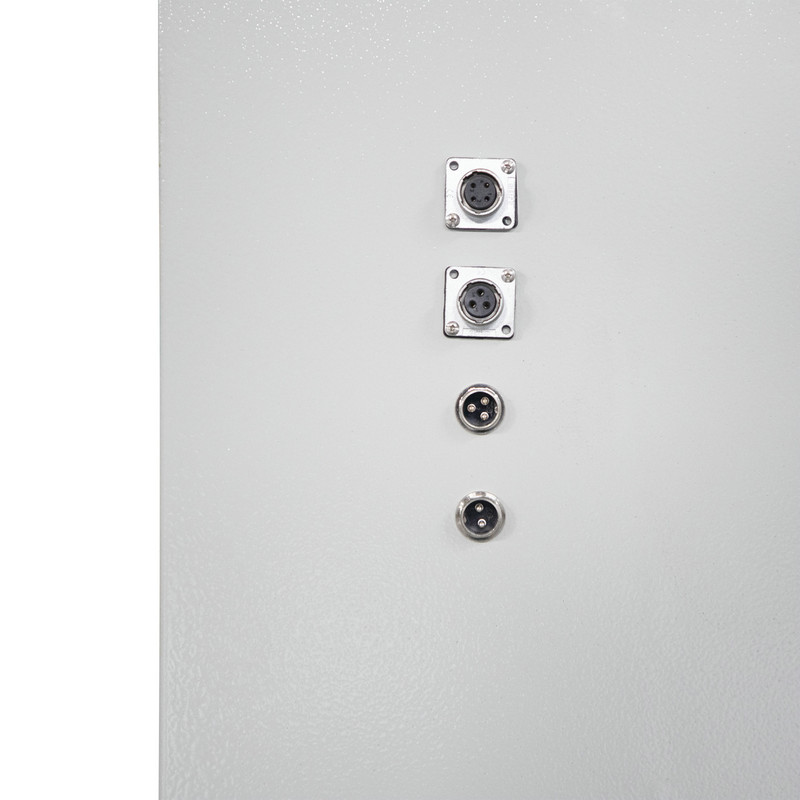

- Integrated Conveying System: Includes a conveying gun and transport tube, enabling smooth and automated nut delivery to robotic welding points.

- Advanced Control Box: Facilitates programmable operation, allowing speed, timing, and feeding intervals to be adjusted for optimal production efficiency.

- Enhanced Production Safety: Automated handling reduces manual contact with components, minimizing workplace hazards.

- Efficiency and Consistency: Standardizes welding time and quality by ensuring nuts are accurately positioned and continuously supplied to the assembly line.

- Flexible Integration: Designed for robotic automation systems, making it suitable for high-volume manufacturing environments.

FAQ

Q1: What nut sizes does the M4-M16 Robot Module support?

A: It supports standard M4 to M16 nuts, covering most industrial assembly requirements.

Q2: Can this module integrate with existing robotic spot welding systems?

A: Yes, it is designed for seamless integration with robotic arms and automated welding machines, ensuring efficient workflow.

Q3: How does the module improve production efficiency?

A: By providing continuous and accurate nut delivery, it reduces manual intervention and standardizes welding operations, improving overall productivity.

Q4: What safety features are included?

A: The system minimizes manual handling of nuts, includes controlled feeding mechanisms, and supports programmable operation to enhance workplace safety.

Q5: Is it suitable for high-volume manufacturing?

A: Yes, the module is engineered for high-speed and continuous production, making it ideal for automotive, shipbuilding, and heavy machinery industries.