The M4-M16 Vibration Plate Feeder Screw Conveyor is specifically designed for efficient nut and screw feeding in industrial settings such as automobile manufacturing and shipbuilding. It works in conjunction with spot welding machines, ensuring consistent welding duration and quality. The conveyor system integrates a vibrating plate, screw conveyor tube, feeding gun, and control box, enabling automated, safe, and efficient production processes. This system is ideal for assembly lines that require precise and continuous nut transport.

Detailed Description

- Precision Feeding: Designed to handle screws and nuts from M4 to M16, providing stable and accurate delivery to welding or assembly stations.

- Vibration-Driven Transport: Equipped with a vibrating plate that ensures smooth and uniform movement of fasteners, reducing jams and misfeeds.

- Screw Conveyor Integration: The tubular screw conveyor efficiently guides fasteners from the vibrating plate to the delivery point, minimizing handling errors.

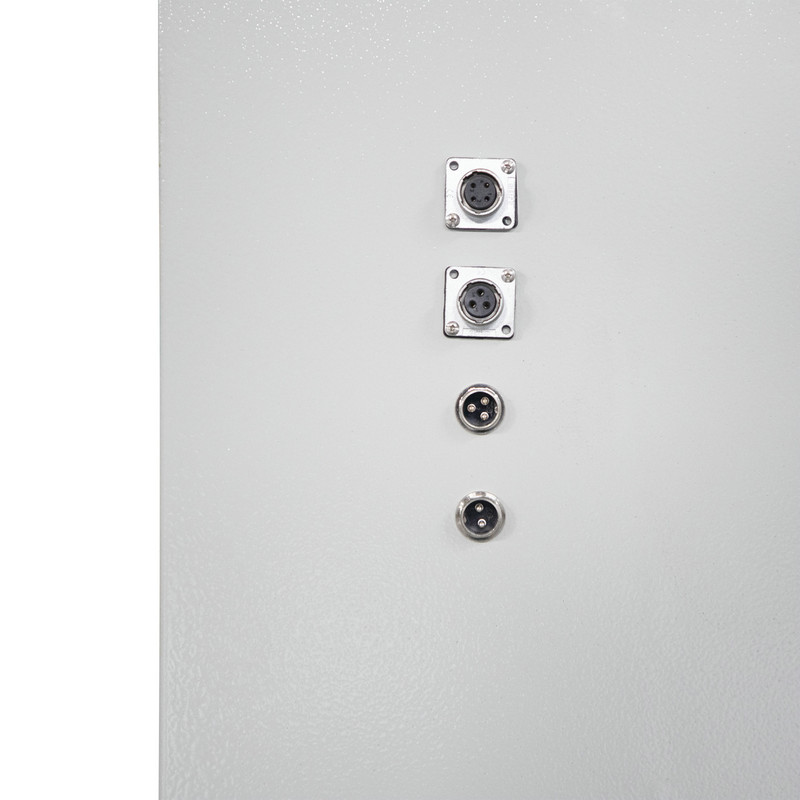

- Control Box Functionality: The integrated control box allows for adjustable feeding speed and operational monitoring, supporting automation and synchronization with spot welding processes.

- Durable Construction: Built with high-quality materials, ensuring long-term reliability in demanding industrial environments.

- Operational Efficiency: Enhances production speed and consistency, reducing downtime and manual intervention.

- Safety Features: Designed to meet industrial safety standards, with mechanisms to prevent blockages and equipment damage.

FAQ

Q1: What screw sizes can this feeder handle?

A: The conveyor is suitable for M4 to M16 screws and nuts, covering a wide range of assembly needs.

Q2: Can it be integrated with spot welding machines?

A: Yes, the system is designed to synchronize with spot welding machines, ensuring consistent welding duration and precision.

Q3: How is the feeding speed adjusted?

A: The control box allows for stepless speed adjustment, enabling operators to match production line requirements.

Q4: Is the system durable for heavy industrial use?

A: Yes, the vibrating plate and screw conveyor are constructed with high-strength materials, suitable for automotive and shipbuilding environments.

Q5: Does it support fully automated operation?

A: Yes, the system is fully compatible with automated production lines, reducing manual intervention and improving operational efficiency.