The M4-M16 Flange Nut Single Feed Vibration Plate Feeder is designed for efficient, automated feeding of flange nuts in industrial production lines. Widely applied in automotive manufacturing, shipbuilding, and machinery assembly, this feeder ensures that nuts are delivered in a consistent, orderly manner to spot welding machines, helping maintain standardized welding durations and quality outcomes. Its integrated system supports high safety standards, stable operation, and production efficiency.

Detailed Description

-

Construction and Components:

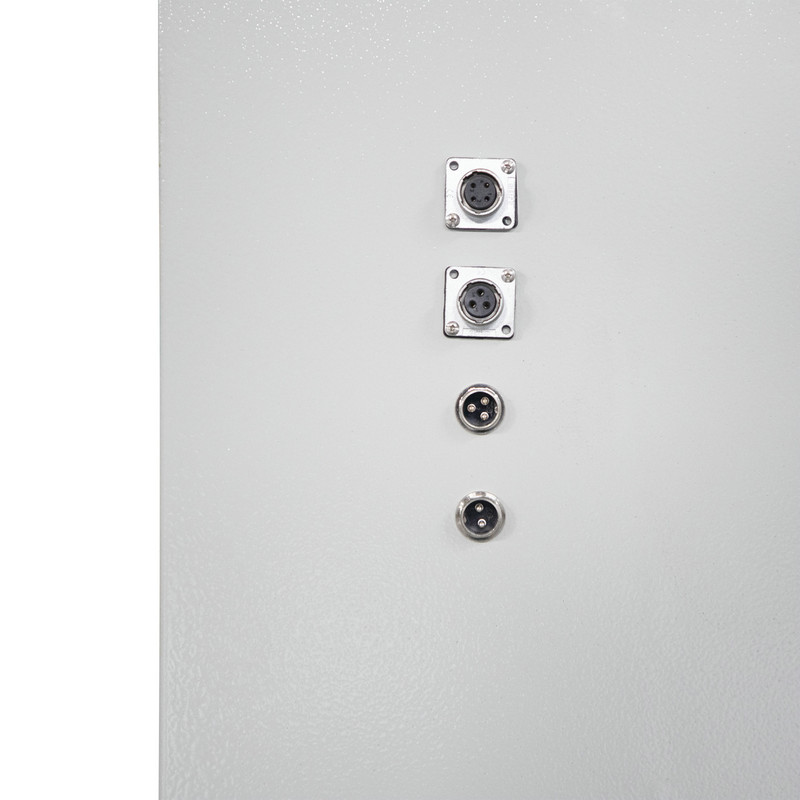

The feeder is composed of a vibrating plate, feeding nozzle, conveying tube, and a control unit, all engineered for durable operation and smooth nut transportation.

-

Precision Nut Feeding:

The single-feed design ensures that each nut is accurately aligned and delivered, preventing misfeeds or jams, and supporting consistent welding operations.

-

Automation & Efficiency:

By coordinating directly with spot welding equipment, the feeder supports automated production lines, improving throughput while reducing manual labor requirements.

-

Adjustable Operation:

The vibration intensity and feeding speed can be precisely controlled via the integrated control unit, allowing adaptation to different nut sizes (M4–M16) and production demands.

-

Safety Features:

Built to meet industrial safety standards, the feeder minimizes risk to operators and equipment while maintaining stable, vibration-controlled nut feeding.

-

Versatility:

Suitable for a variety of flange nut types and sizes, it can be easily integrated into existing assembly and welding systems, providing flexible application in multiple industries.

FAQ

Q1: What nut sizes are compatible with this feeder?

A1: The feeder supports M4 to M16 flange nuts, ensuring adaptability to standard industrial applications.

Q2: Can this feeder be integrated with automatic spot welding machines?

A2: Yes, it is specifically designed to work in tandem with spot welding equipment, ensuring synchronized feeding and welding processes.

Q3: How is the feeding speed controlled?

A3: The control unit allows precise adjustment of vibration intensity and feed rate, enabling optimization for different nut sizes and production requirements.

Q4: Is this feeder suitable for continuous industrial operation?

A4: Yes, it is engineered for high durability and can operate in continuous production environments without compromising performance.

Q5: How does the feeder ensure safety during operation?

A5: The stable vibration mechanism and controlled feeding system reduce the risk of jams and operator contact, ensuring a safe operational environment.