Product Advantages

The DTN2-150KW LCD Display Parameter Pneumatic Spot Welder provides a combination of efficiency, reliability, and precision:

- High Welding Efficiency: Minimal sparks during operation reduce material loss and increase safety.

- Consistent Weld Quality: Advanced microcomputer control ensures uniform and robust welding results every time.

- Wide Voltage Adaptability: Incorporates wide-voltage technology, allowing automatic voltage adjustment within a ±20% range for stable performance under different power conditions.

- User-Friendly Operation: The LCD display and intuitive interface allow easy monitoring and adjustment of welding parameters.

Key Features

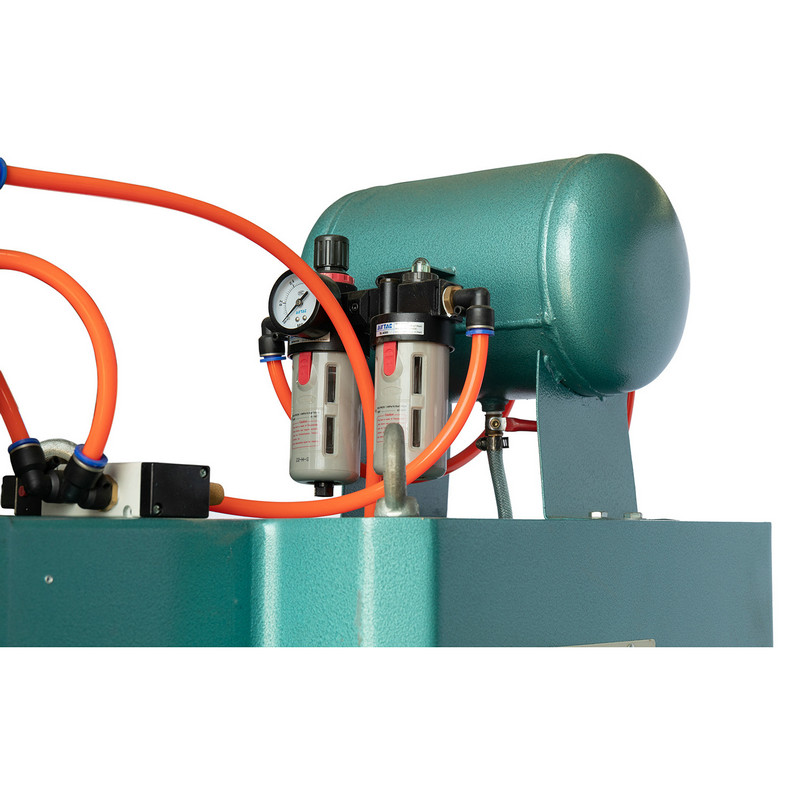

- Microcomputer Control System: Facilitates precise adjustment of welding parameters such as pressure, welding current, duration, maintenance interval, and rest period.

- All-Copper Transformer: Ensures efficient energy transfer, long service life, and stable output.

- Minimal Sparks Welding: Reduces safety risks and improves overall work efficiency.

- Versatile Material Compatibility: Suitable for hot and cold plates, stainless steel plates and wires, nuts, and other workpieces.

Applications

The DTN2-150KW is ideal for industries and tasks requiring high-precision spot welding:

| Application Area |

Typical Use Case |

Benefits |

| Automotive Components |

Welding stainless steel and sheet metal parts |

Reliable welds with minimal sparks |

| Electronics and Appliances |

Assembly of metal housings and frames |

Accurate and consistent welding |

| Hardware Manufacturing |

Nuts, fasteners, and wire welding |

Strong welds and improved production efficiency |

| Metal Fabrication |

Hot and cold plate welding |

Adaptable to different material thicknesses |

Operational Advantages

- Customizable Settings: Operators can easily modify parameters directly via the microcomputer controller, optimizing for different workpieces.

- Efficient Workflow: The system allows rapid setup and adjustments, minimizing downtime.

- Enhanced Safety: Controlled welding process with minimal sparks and heat generation reduces risk of accidents.