The DZN-100 1000 Hz Medium Frequency Spot Welder is a touchscreen-controlled spot welding system designed for high-power, high-conductivity welding tasks. By converting the supply frequency to 1000 Hz and raising the transformer operating frequency accordingly, the unit increases secondary-loop inductance, enabling reliable welding of thick materials and highly conductive metals such as aluminum and galvanized steel. The welder’s integrated display shows real-time welding current and provides immediate fault/error alerts, making it suitable for demanding production environments in new energy vehicles, home appliances, and construction industries.

Detailed description (features & advantages)

-

Touchscreen control & user interface

- Intuitive touchscreen enables fast parameter setting and process monitoring.

- On-screen readout shows welding current in real time and logs immediate fault/error notifications for quick troubleshooting.

-

1000 Hz medium-frequency conversion

- The converter raises the system frequency to 1000 Hz, and the transformer frequency is elevated to match.

- This frequency shift increases the secondary-loop inductance, concentrating energy delivery and improving weld penetration on thicker sections.

-

Optimized for high-conductivity and thick materials

- Engineered to weld aluminum, galvanized steel, and other highly conductive metals that are difficult for conventional low-frequency spot welders.

- Enhanced performance when joining thick panels or multi-layer stacks, reducing rework and improving joint consistency.

-

Stable, repeatable welding performance

- Medium-frequency architecture provides stable energy output and consistent heat generation across cycles, improving repeatability in production runs.

- Reduced heat-affected zone and controlled energy transfer help maintain material properties at the joint.

-

Safety and fault management

- Built-in monitoring reports over-current, under-current, and system faults on the display, enabling immediate operator response.

- Designed with production safety and uptime in mind to minimize unexpected stoppages.

-

Flexible industrial applications

- Widely adopted in new energy vehicle battery assembly and structural welding, home appliance panel fabrication, and construction-grade sheet joining.

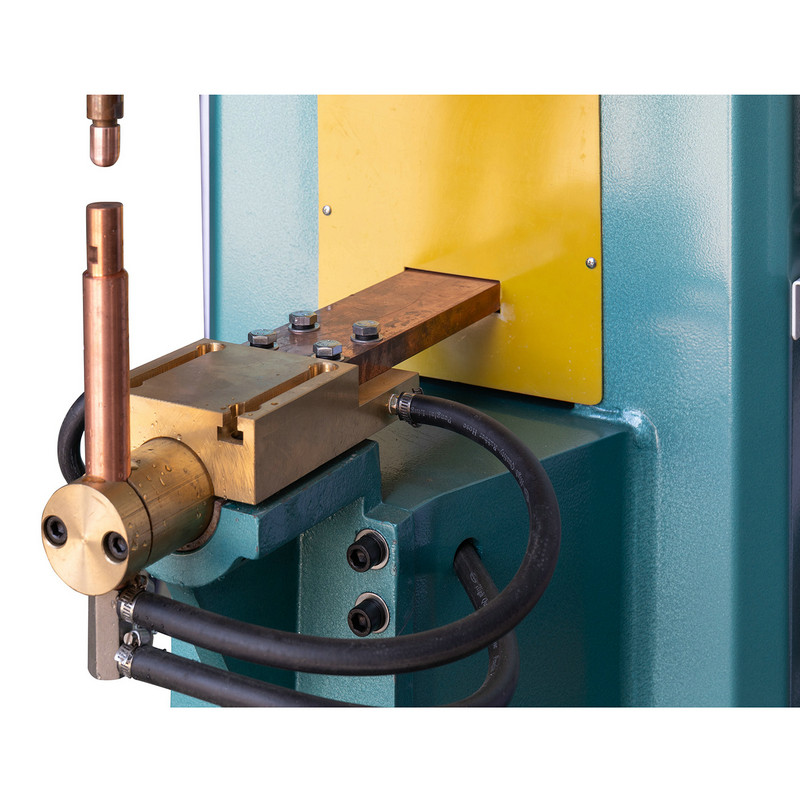

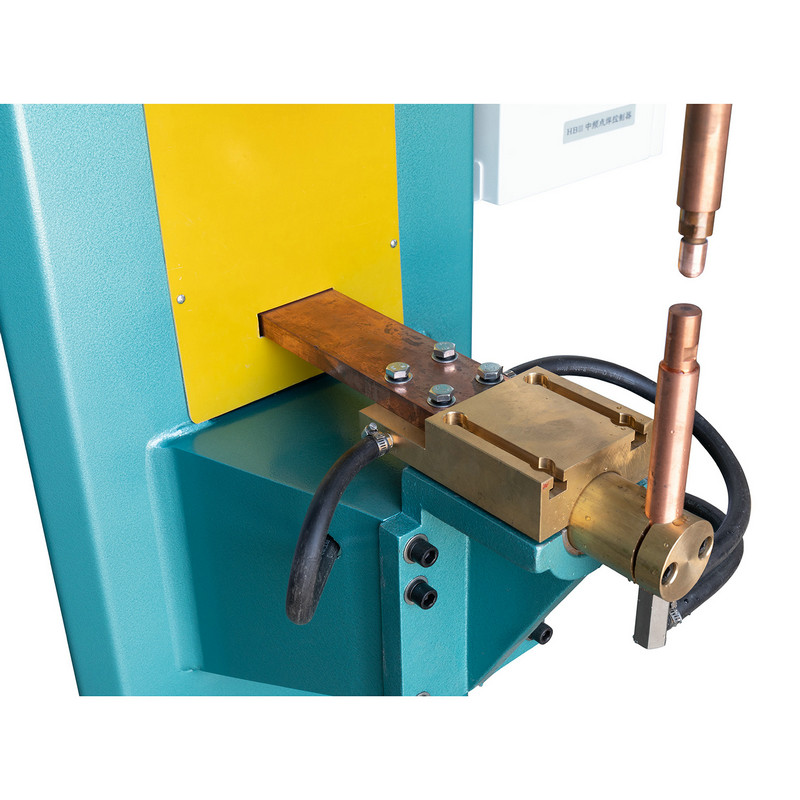

- Compatible with standard spot-welding electrodes, fixtures, and secondary-loop arrangements used in automated or manual production lines.

-

Serviceability and integration

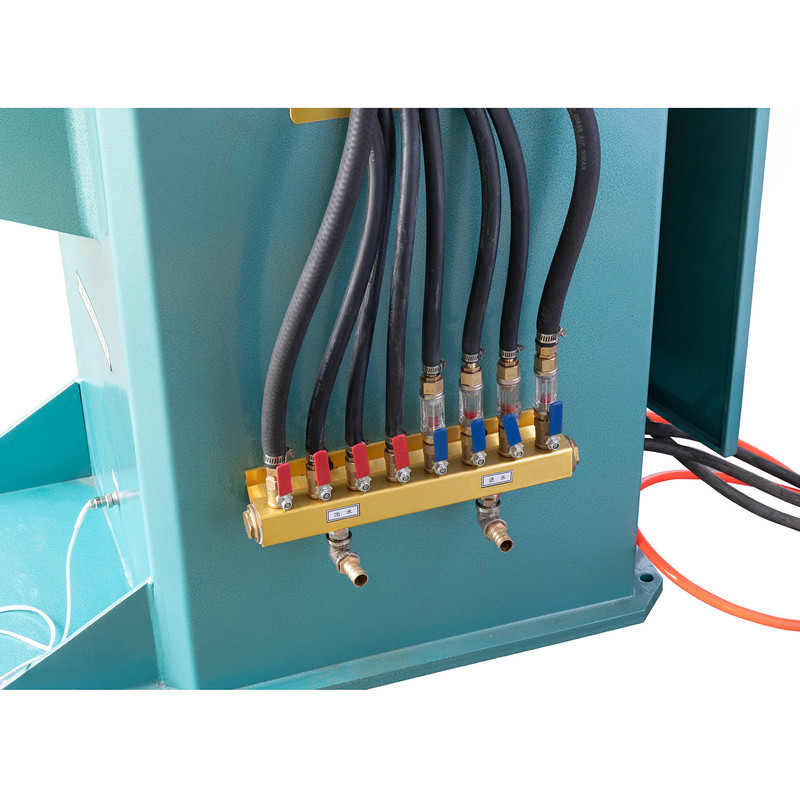

- Modular frequency-conversion components and accessible transformer design simplify maintenance and integration into existing welding cells.

- Digital interface supports quick changeovers and parameter backups for repeat jobs.

DZN-100 1000 Hz Medium Frequency Spot Welder delivers targeted energy control and robust fault feedback, making it a practical choice where high conductivity, material thickness, and production reliability are primary concerns.