The DZN-50 Metal Shell Medium Frequency Spot Welder is a compact, metal-enclosed medium-frequency spot welder designed for reliable resistance welding of thick workpieces and highly conductive metals. The unit is controlled by a touch screen that displays real-time welding current and provides timely fault and error warnings. Its control system inverts the supply to 1000 Hz, and the transformer is operated at 1000 Hz, which optimizes the secondary loop inductance for improved performance when welding materials such as aluminum and galvanized steel. The DZN-50 is suitable for applications in new energy vehicles, home appliances, construction, and related industries.

Detailed Explanation (Features & Advantages)

-

Touch-screen Control & Monitoring

- Touch screen interface for intuitive operation.

- Real-time welding current display enables accurate process monitoring.

- Immediate fault and error warnings for faster troubleshooting and safer operation.

-

Medium-Frequency Inverter System

- Built-in inverter converts the input to a 1000 Hz output frequency.

- Transformer also runs at 1000 Hz, reducing magnetic core size and improving dynamic response compared with line-frequency designs.

-

Optimized Secondary Loop Inductance

- Increased operating frequency raises the effective secondary loop inductance, stabilizing welding current for thick materials and highly conductive metals.

- Results in more consistent heat generation at the weld nugget and improved weld quality for challenging materials such as aluminum and galvanized steel.

-

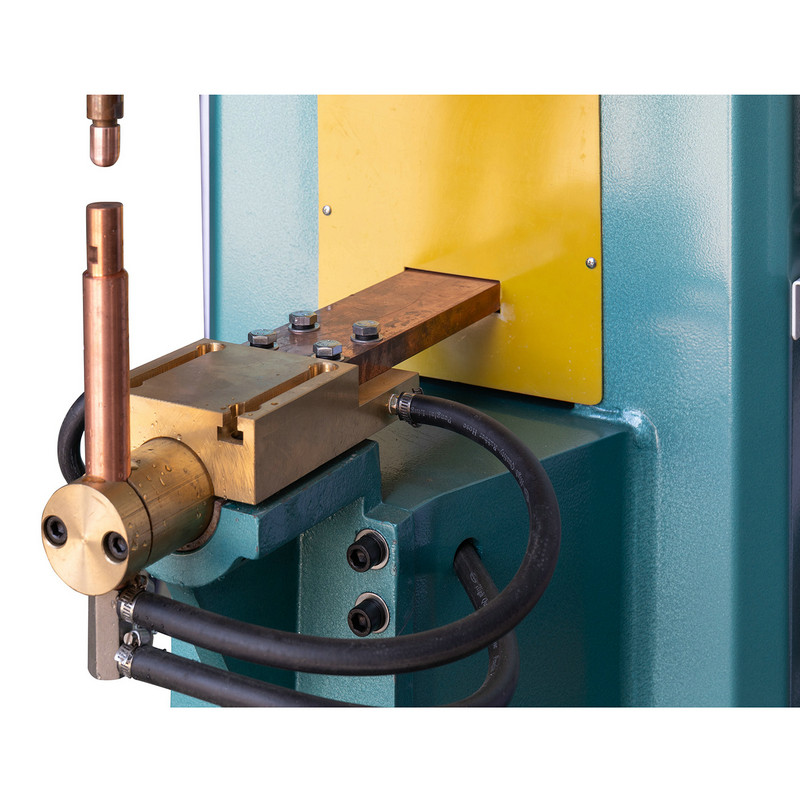

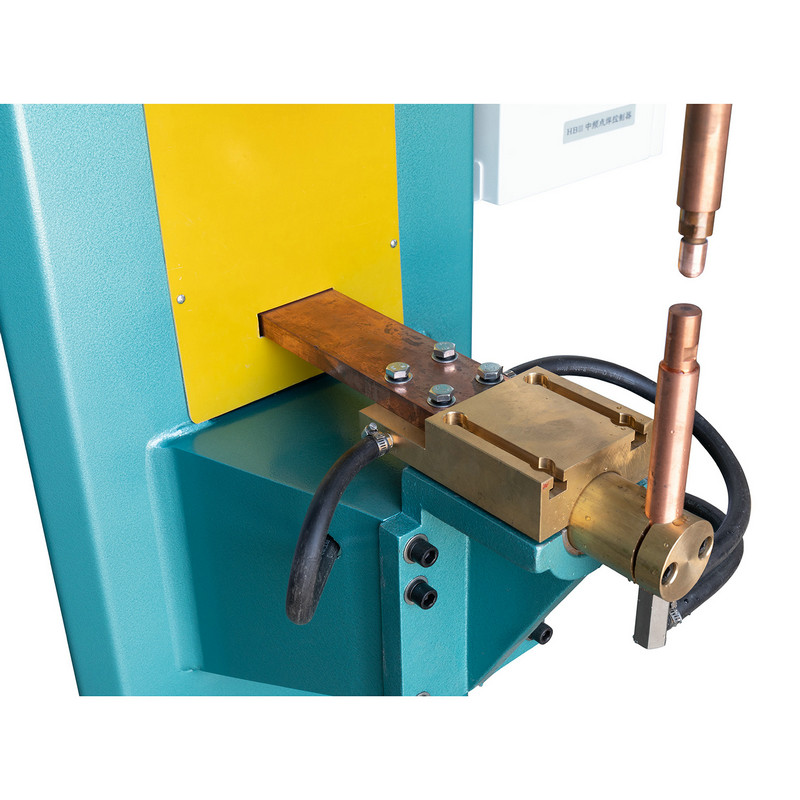

Robust Metal Shell Construction

- Metal enclosure provides mechanical protection and electromagnetic shielding, suitable for industrial environments.

- Simplifies installation in production lines for automotive, appliance, and construction manufacturing.

-

Application Versatility

- Engineered for resistance spot welding of thick plates, busbars, and components with high electrical conductivity.

- Widely applicable to new energy vehicles (battery packs, frames), home appliances (cabinet and component assembly), and construction metalwork.

-

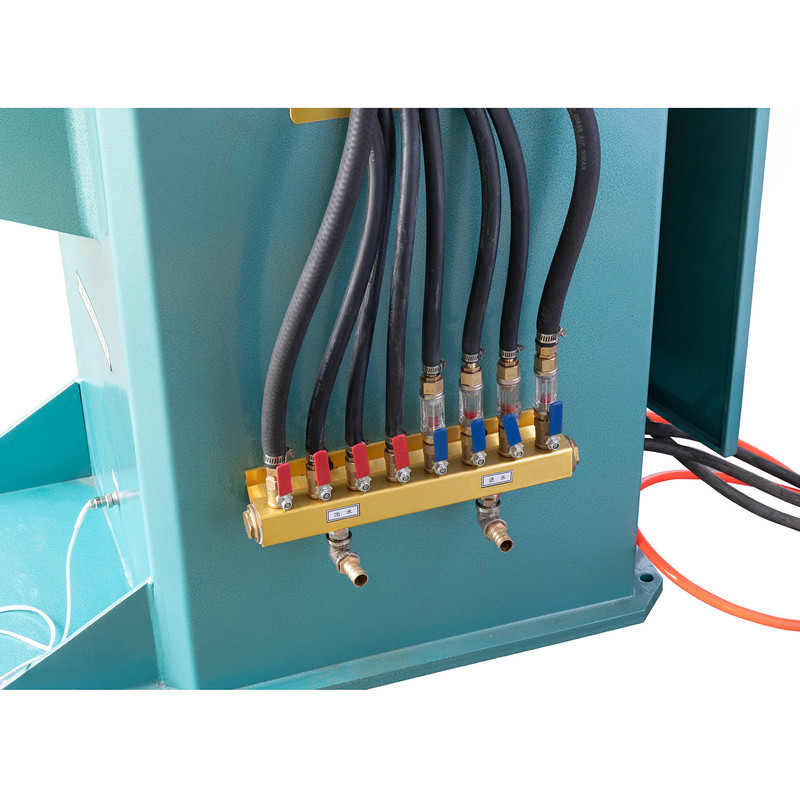

Safety & Maintainability

- Integrated fault reporting reduces diagnostic time and supports preventive maintenance.

- Modular design of power and control units facilitates service and spare-parts replacement.

-

Key Product Terms (for specification and procurement)

- Model: DZN-50

- Type: Metal shell medium-frequency spot welder / resistance spot welder

- Control: Touch-screen controller, welding current display, fault warnings

- Frequency: 1000 Hz inverter and transformer operation

- Suitable materials: Aluminum, galvanized steel, other high-conductivity metals

- Typical uses: EV battery and chassis assembly, appliance panel welding, construction components