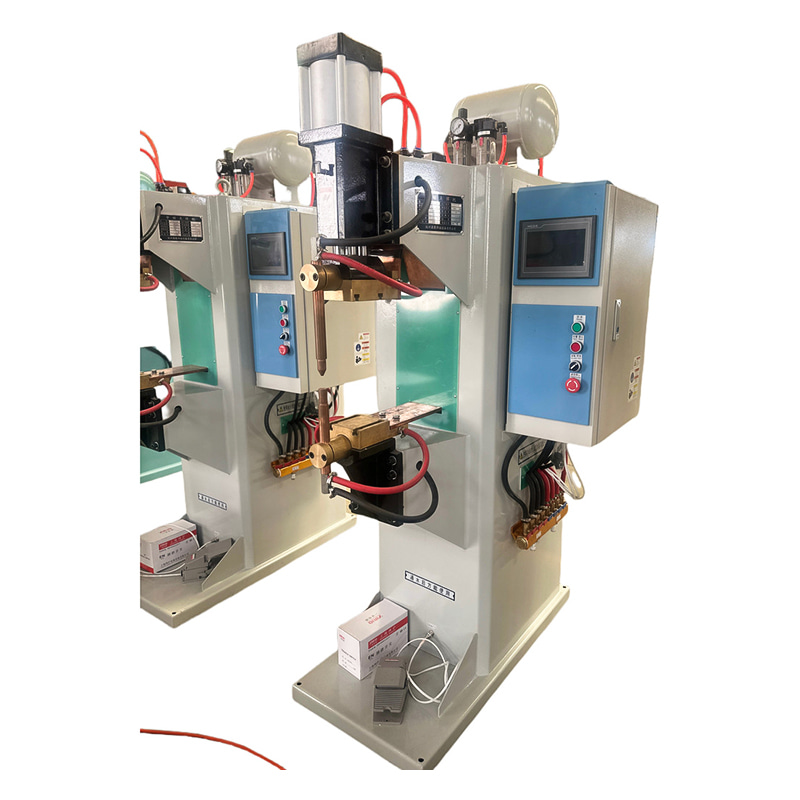

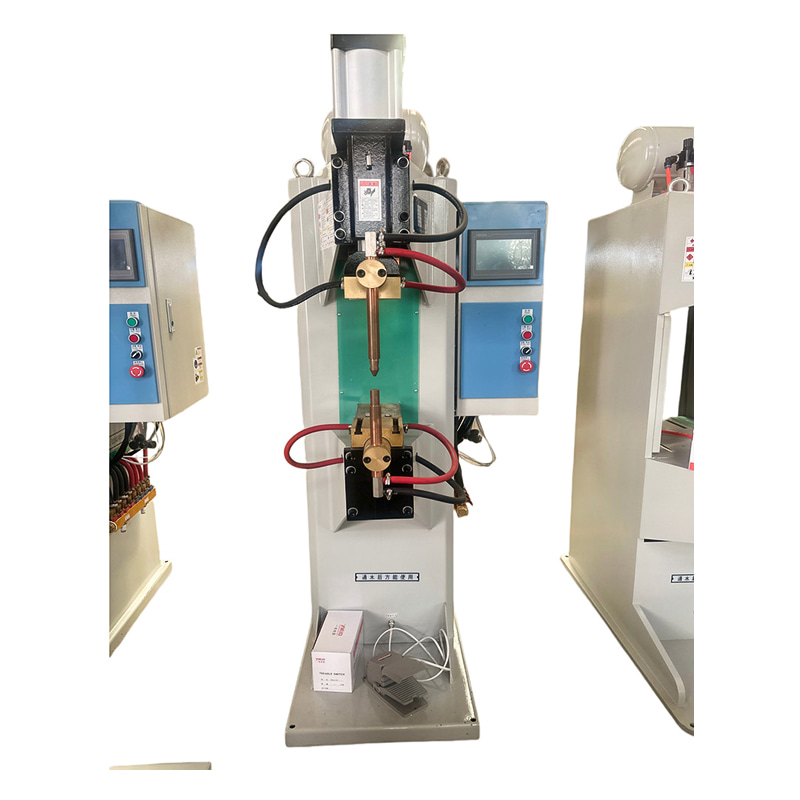

TN-20KA is a medium-frequency spot welding machine designed for welding thick workpieces and high-conductivity metals. Controlled via a touchscreen, the unit provides a clear welding current display and real-time fault/error alerts. By converting the input voltage frequency to 1000Hz and matching the transformer frequency at 1000Hz, the system increases the secondary loop inductance, making the TN-20KA particularly well suited for materials such as aluminum and galvanized steel. Its robust performance and adaptability make it a common choice in industries including new energy vehicles, home appliances, and construction.

Key features and advantages

-

Touchscreen control & monitoring

- Touchscreen interface for intuitive operation.

- Real-time welding current readout and immediate fault/error indications, improving operator response and reducing downtime.

-

1000Hz medium-frequency system

- Input voltage is converted to 1000Hz and the transformer frequency is elevated to 1000Hz.

- This frequency increase raises the secondary loop inductance, which stabilizes arc behavior and improves energy transfer for thicker and highly conductive materials.

-

Optimized for thick and high-conductivity metals

- Engineered for reliable joining of thick workpieces and high-conductivity metals (notably aluminum and galvanized steel).

- Produces consistent welds where conventional low-frequency systems may struggle.

-

Wide industry applicability

- Developed for manufacturing environments in new energy vehicles, home appliance assembly, and construction components, where thicker sheets and conductive materials are common.

-

Improved weld quality and process stability

- The higher medium frequency and resulting inductance reduce the risk of poor fusion or burn-through on conductive metals and help achieve repeatable weld profiles.

-

Operator safety and maintenance

- Fault alerts on the display enable faster troubleshooting.

- Simpler diagnostics via the interface reduce maintenance time.

Technical & Application Notes (concise)

- Machine type: Medium-frequency spot welder (inverter-based).

- Control: Touchscreen with current readout and fault alerts.

- Frequency: 1000Hz system conversion (input and transformer matched).

- Electrical effect: Increased secondary loop inductance for improved welding behavior on conductive/thick materials.

- Typical materials: Aluminum, galvanized steel, and other high-conductivity metals.

- Typical industries: New energy vehicles, home appliances, construction.

Comparison with Similar Products

| Feature / Metric |

TN-20KA (1000Hz) |

Conventional Low-Frequency Spot Welder (50/60Hz) |

Standard MF Spot Welder (≈500Hz) |

| Operating frequency |

1000Hz |

50 / 60 Hz |

≈500Hz |

| Transformer frequency match |

Yes — matched to 1000Hz |

No — mains frequency |

Matched to ~500Hz |

| Secondary loop inductance |

Higher (improved for thick/conductive metals) |

Lower |

Moderate |

| Suitability for thick workpieces |

High |

Low–moderate |

Moderate–high |

| Suitability for aluminum / galvanized steel |

Excellent |

Poor–moderate |

Good |

| Control & monitoring |

Touchscreen, current readout, fault alerts |

Basic analog/digital controls |

Varies; often basic digital |

| Weld quality consistency on conductive metals |

High |

Variable |

Good |

| Typical applications |

New energy vehicles, home appliances, construction |

Light assembly, thin-sheet welding |

General manufacturing, thicker sheets but less conductive metals |

| Maintenance & diagnostics |

Easier — on-screen alerts |

Manual troubleshooting |

Varies; less advanced than TN-20KA |

| Energy transfer efficiency for thick conductive parts |

Optimized |

Less optimized |

Reasonable but lower than 1000Hz approach |

| Typical operator learning curve |

Moderate (touchscreen simplifies use) |

Low–moderate |

Moderate |