The DBN-100 Operation Model Storage Inverter Frequency Spot Welding Machine is designed for high-load industrial welding applications, combining robust construction with advanced inverter technology. Its structure includes a solid frame, pressure application mechanism, inverter housing, control unit, AC transformer, gas and water circuits, and secondary connection components, ensuring reliable performance and long-term durability. By maintaining three-phase balance and reducing grid voltage interference, the DBN-100 delivers stable and efficient welding operations suitable for multi-point projection welding and spot welding of automotive components and industrial machinery parts.

Detailed Description

Key Features & Advantages:

-

Robust Structure:

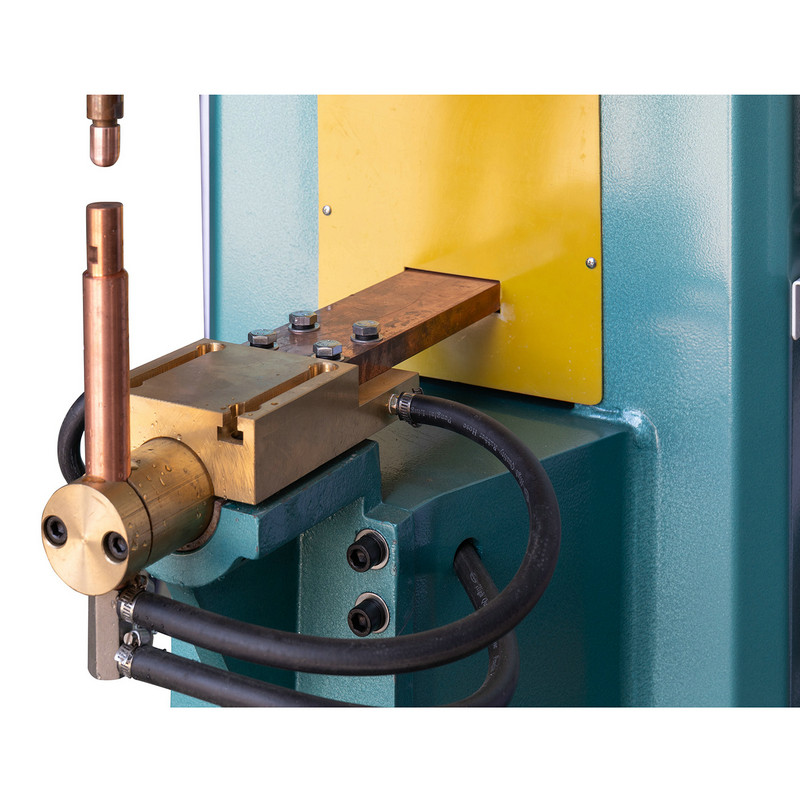

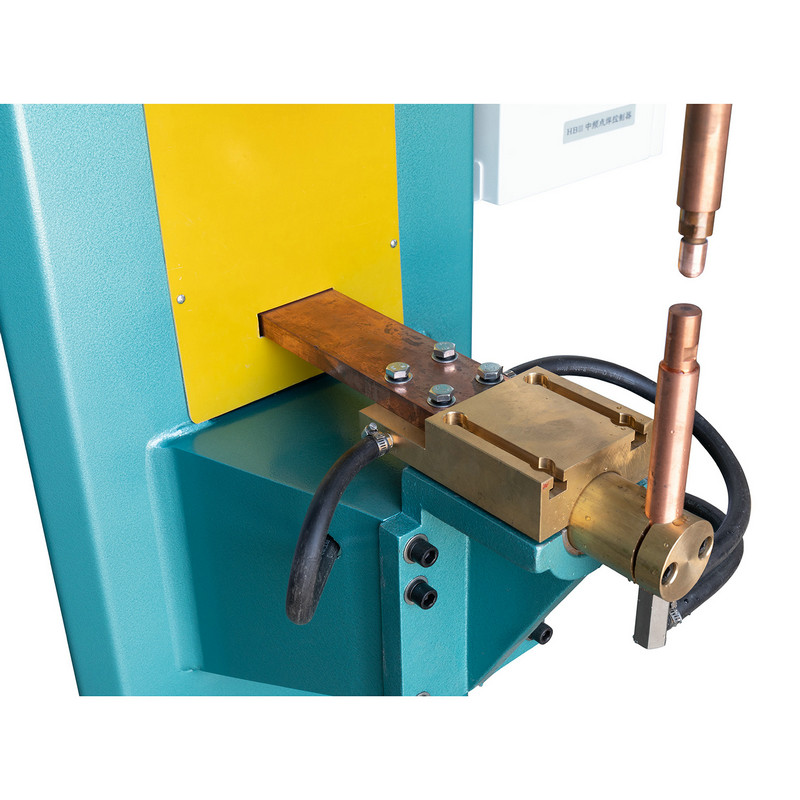

- Integrated frame and pressure mechanism provide stability during heavy-duty welding operations.

- Inverter housing and control unit safeguard electronics while allowing precise operation control.

-

Advanced Welding Performance:

- Inverter frequency technology ensures consistent energy delivery, improving weld quality.

- AC transformer with optimized secondary loop supports welding of thick materials and high-conductivity metals.

-

Electrical Efficiency & Stability:

- Maintains three-phase balance, reducing the risk of power fluctuations.

- Minimizes grid voltage contamination, protecting both the machine and connected electrical systems.

-

Versatile Industrial Applications:

- Suitable for multi-point projection welding, ensuring uniform welds across multiple locations.

- Ideal for spot welding in automotive manufacturing, industrial machinery, and metal component assembly.

-

Cooling & Maintenance:

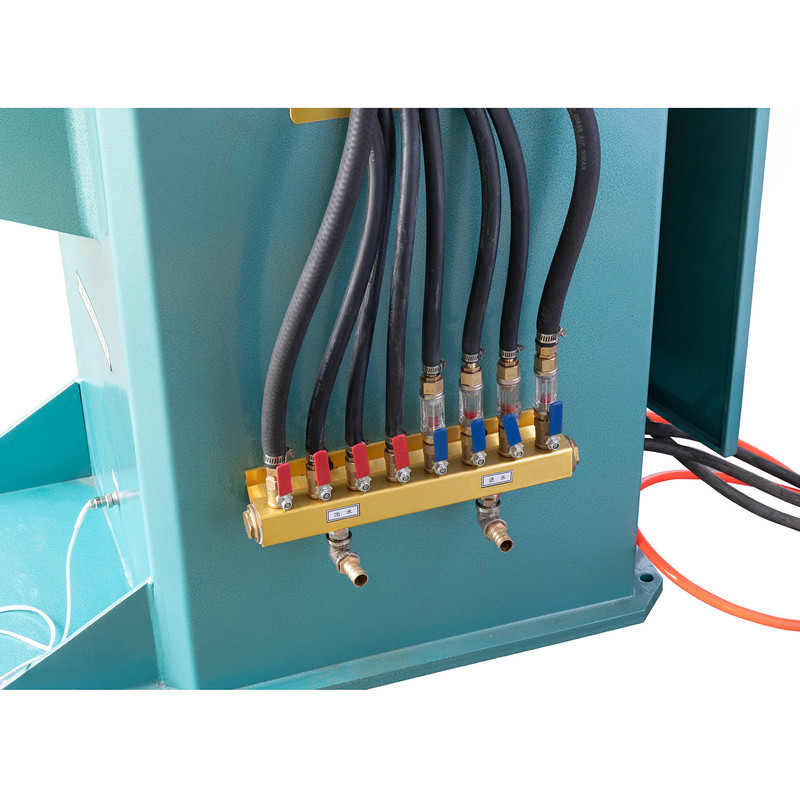

- Integrated gas and water circuits provide effective cooling for high-frequency operations, extending machine lifespan.

- Secondary connection components designed for quick and secure installation.

FAQ

Q1: What types of materials can the DBN-100 weld?

A: It can efficiently weld high-conductivity metals, including aluminum, galvanized steel, and thick metal sheets.

Q2: Is the machine suitable for multi-point welding?

A: Yes, the DBN-100 is optimized for multi-point projection welding, ensuring consistent weld quality across multiple contact points.

Q3: How does the DBN-100 ensure electrical stability?

A: By maintaining three-phase balance and reducing grid voltage interference, it provides stable energy output and protects connected electrical systems.

Q4: What cooling system does the machine use?

A: The machine integrates gas and water circuits to effectively dissipate heat, supporting continuous high-frequency operation.

Q5: In which industries is the DBN-100 commonly used?

A: It is widely used in automotive manufacturing, industrial machinery production, and general metal component fabrication.